DATE RANGER

| Capacity | 3 - 30 m3/s |

| Head | 3 - 18m |

| Working Temperature | 0 - 60 ºC |

| Speed: | n= 180 ~ 1000rpm |

| Voltage | ≥ 380V 6kV 10kV |

| Pump diameter | Ф= 1200mm ~ 2800mm |

PRODUCT DESCRIPTION

Why choose us?

· Specialized production Manufacturer for Vertical Turbine Pump

· Focus on technological innovation, Over Industry leading level

· Good experience at Domestic and oversea market

· Carefully paint for Good appearance

· Years of International service standards, Engineer one-to-one service

VTP vertical axial-(mixed)-flow pump is a new general-elation product successfully developed by this Company by means of introducing the advanced foreign and domestic know how and meticulous designing on the basis of the requirements

from users and the conditions of use. This series product uses the latest excellent hydraulic model, wide range of high efficacy, stable performance and good vapor erosion resistance; the impeller is precisely cast with a wax mould, a smooth and unimpeded surface, identical accuracy of the cast dimension to that in design, greatly reduced hydraulic friction loss and shocking loss, a better balance of impeller, a higher efficiency than that of the common impellers by 3-5%.

CONDITION FOR USE

Suitable for pumping pure water or other liquids of the physical chemical natures similar to those of pure water.

Medium density: 1.05 10 kg/m

PH value of medium:between 5~11

ADVANTAGE

Slowly pump speed design conforms to the technological requirements of salting out and low temperature crystallization.

Vertical axial flow pumps are widely used in salt works, obtaining salt by evaporating brine, composite alkali process, etc. Selecting corrosion-resistant materials and high-strength shafts to ensure smooth operation and long service life of vertical axial flow pumps.

Specially designed to suit different applications.

With the help of our professional engineers, special design could be carried out to increase the head, increase the guide vane body, and realize the function of a vertical mixed-flow pump; Wear resistant coating is added to the impeller for the medium containing corrosive and hard particles, so that the service life of the vertical pump is greatly extended. Increasing the system pressure and liquid level can achieve the purpose of forced circulation.

We producing reliable operation, high efficiency, long lifetime and big diameter vertical axial flow pumps. Highly customized of vertical axial flow pumps, meet end users' requirements, as well as have lots of references of vertical axial flow pumps.

For the installation of large equipment, also provide service for installation of vertical axial flow pump on site or remote technical instruction.

A wide range of high-quality materials deal with different medium, such as cast iron, carbon steel, stainless steel SS304, SS316, SS316L, 904L, Duplex stainless steel CD4MCu, 2205, 2507...

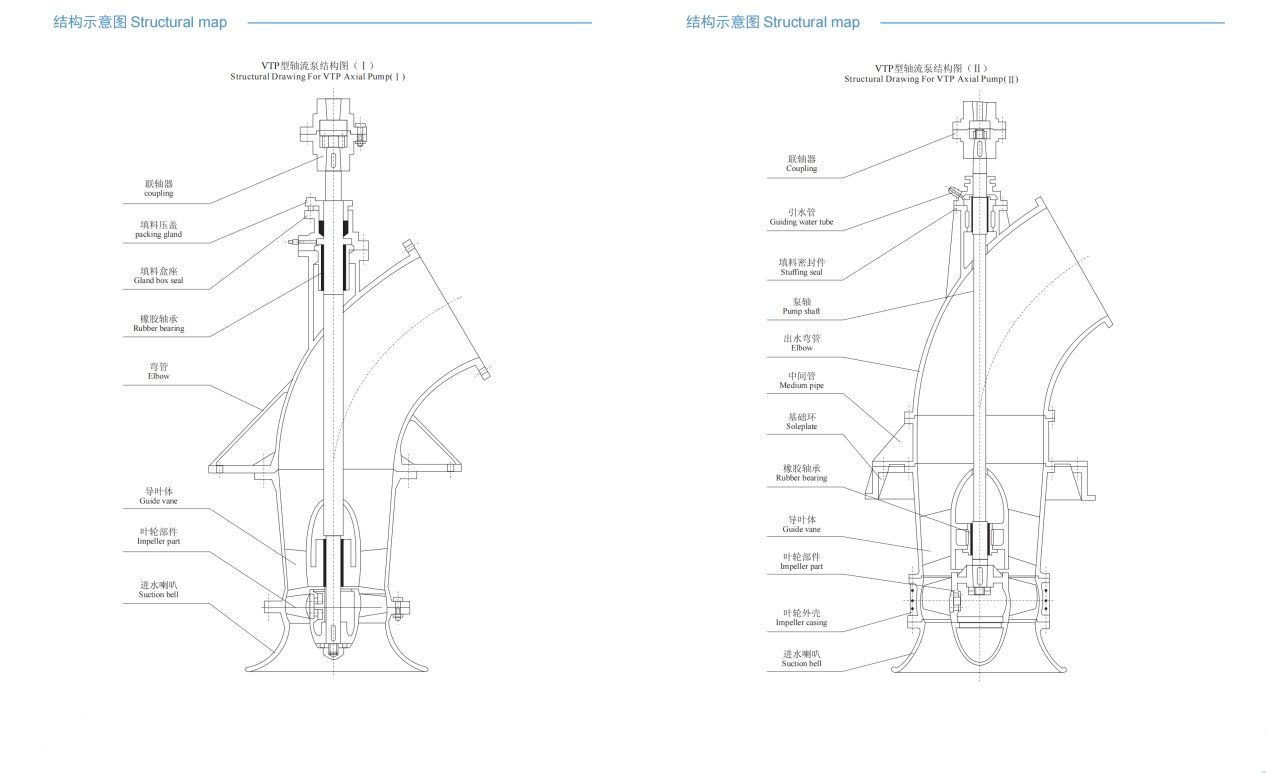

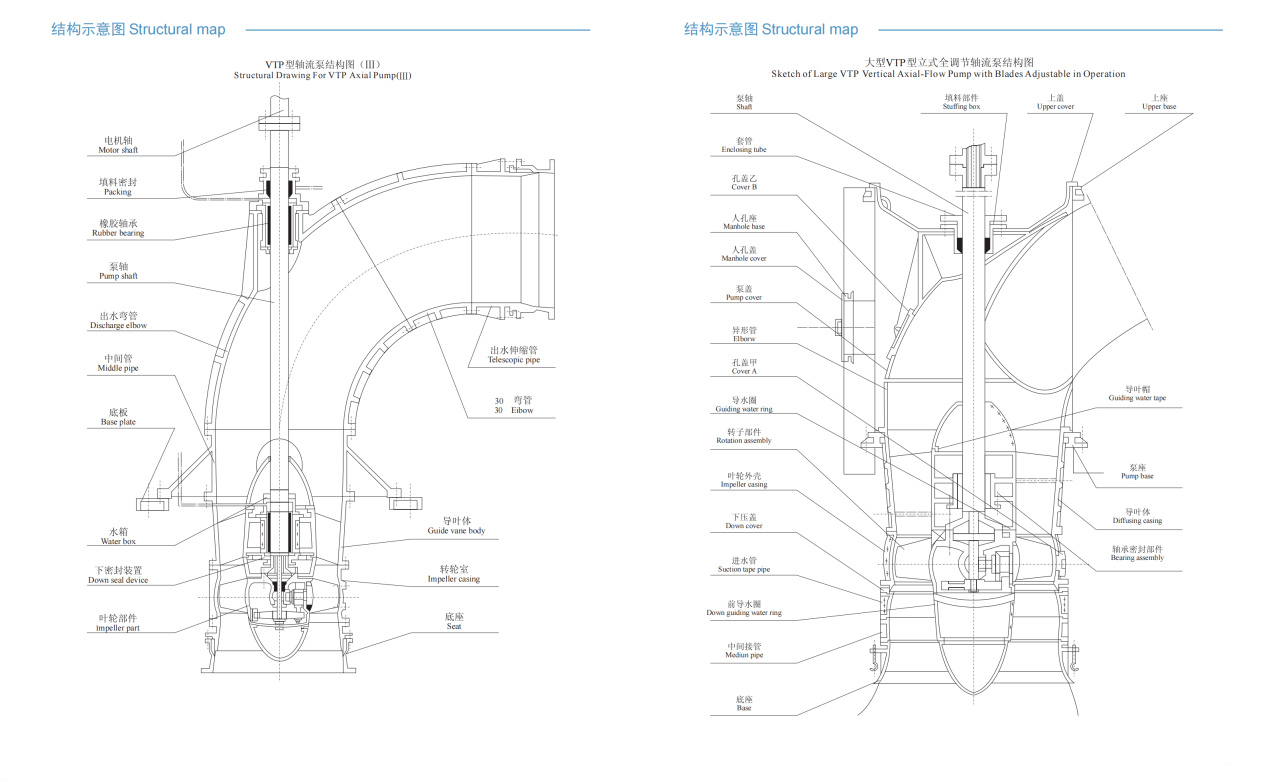

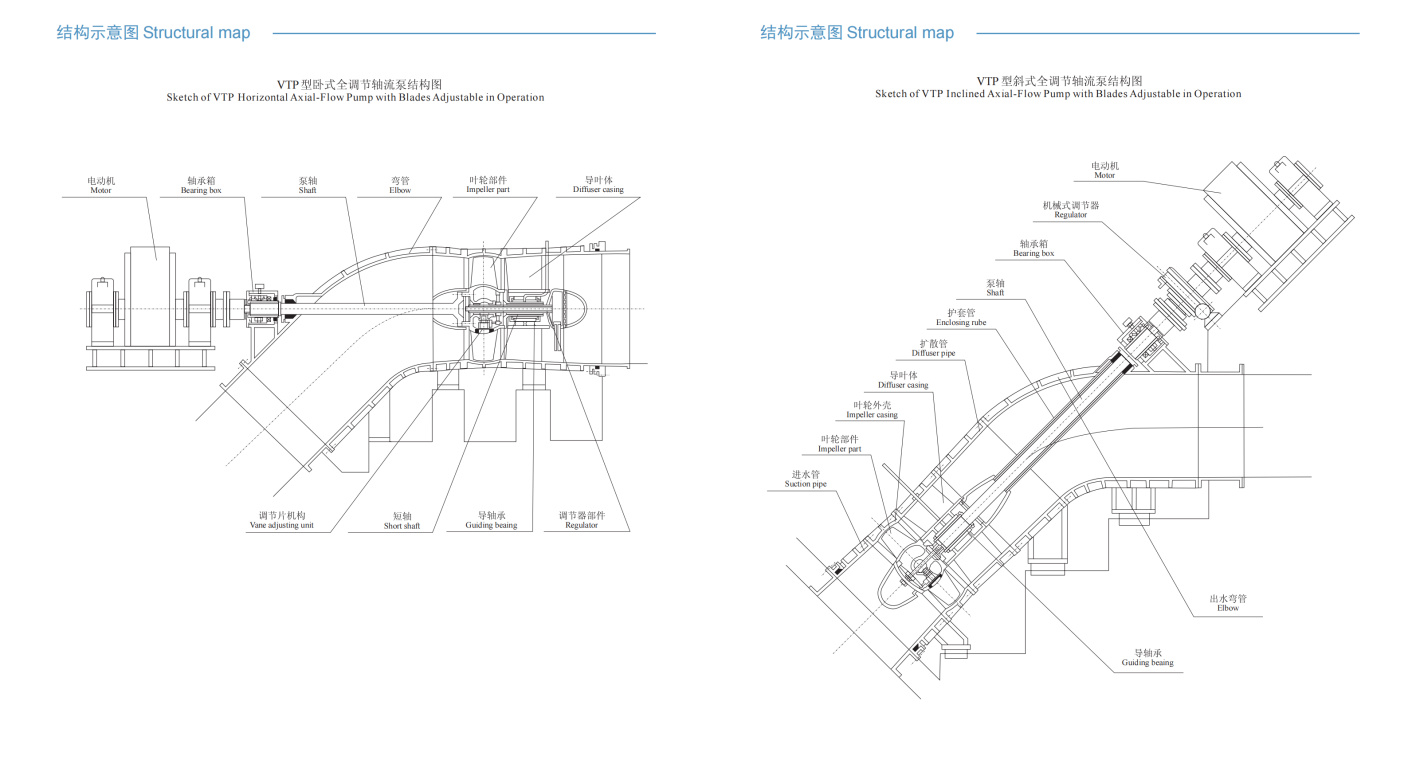

STRUCTURE

VTP series products are all of a vertical structure and fitted with a vertical motor.

With a variety of structural design to meet a variety of complex site needs.

With the impeller there are fixed, semi-adjustable and fully-adjustable type. The fixed type means both impeller and hub are cast integrally and the impeller angle is NOT Adjustable; the semi-adjustable type means the impeller can be turned to the desired angle by loosening the fixing screw on it in case the working conditions need to be changed, then fix all the impellers again; VTP is the fully adjustable type, that means the impeller angle can be adjusted through a mechanical or hydraulic adjust-or with or without stopping.

Vertical axial-(mixed)-flow pump consists of the pump casing and the actuating part. The pump casing generally includes water inlet pipe, impeller, guide vane, pump shaft, elbow, middle pipe,sealing unit and clutch. For both middle and small pumps, a water inlet horn is used as the water inlet pipe while, for the large one, a toggle or bell water inlet passage is used, poured with concrete and fitted with imported basic parts. The adjustable impeller is formed with blade(stainless steel or copper alloy, in general), hub, water guide cone. For the middle and small pumps, both impeller and pump shaft are connected with flat pin and nut while, for the large and fully djustable ones, a flange is used to connect both hub and main shaft. The pump

s guide bearing is a rubber one and can be lubricated with going-through water or additional pure water. When lubricated with the going-through water, it has to be done to supply water for the rubber bearing on the upper side via a water-led pipe and do not stop until water comes out of the pump normally.

Both middle and small pumps are directly actuated by a vertical motor, the motor is mounted on the motor seat and connected with the actuating shaft via an elastic clutch. Inside of the motor seat there are radial and thrust bearings, lubricated with engine oil or grease; for the one of a bigger power there is a water cooling mezzanine. Large pump is fitted with a large vertical motor, directly mounted on the motor s basic beam, and both motor shaft flange and pump shaft flange (hinged hole) are linked with bolt. The axial force of the pump is borne by the thrust bearing of the large vertical motor.

The pump moves clockwise viewing from the motor.

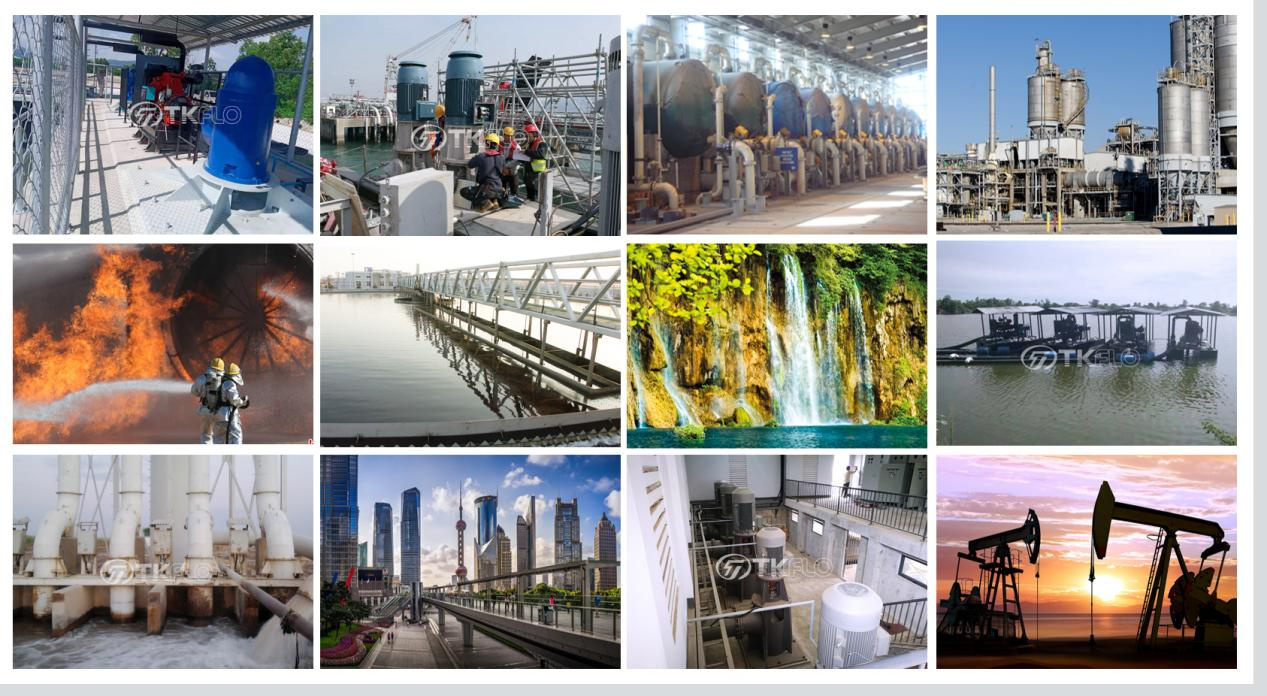

Extensively used for hydraulic projects, farm-land irrigation, industrial water ransportation, water supply and drainage of cities and water allocation engineering.

APPLICANT

OUR VTP SERIES high efficiency large capacity vertical axial or mix flow water pump have a wide range of applications

Hydraulic projects;

Industrial water transportation;

Agricultural drainage and irrigation;

Water supply and drainage of power station;

water supply and drainage of cities and water allocation engineering;

Water supply and drainage of docks;

Electricity/ power station circulating water transferring;

Dock water level rising and lowering;

Sea water desalination / Salt works draw water;

Phosphoric acid, obtaining salt by evaporating seawater and other chemical industries;

Big flow with low total head.

seth@tkflow.com

seth@tkflow.com