Overview Of Product

● Advantage

Lower construction cost

Intelligent control for safe operation

Easy Installation

Submergence resisting

Lower running cost

Environmental protection

● Details Characteristic advantage for WQ series Submersible Sewage pump

1. Most of the impellers with the pump of an aperture below 400 come as a bi-runner impeller and few of them is a multi-blade centrifugal impeller. While most of the impellers with the pump of an aperture 400 and above come as a mixed flow impeller and few of them is a bi-runner impeller. The spacious pump casing runner lets the solids easily passing and the fibers uneasily wrapping so that it is most suitable for discharging sewage and dirt.

2. Two independent single end-face mechanical seals are in-series mounted, with the installation mode as the internal installation mode, and, compared with the external installation mode, the medium is more uneasy to leak and also its sealing friction pair are easier lubricated by the oil in the oil chamber. A special spiral slot or a small seam is used to resist the solid grains to be deposited on the mechanical seal by the pump to make sure of its stable work. The unique mechanical seal layout mode and bearing combination makes the suspension arm of the shaft short, a heavy rigidity and a small jump, more benefit for reducing the leak from the mechanical seal and extending the life of it.

3. The motor of a protective grade IPX8 works in submerged mode and holds the best cooling effect. The grade F insulation makes the winding bearable to a higher temperature and, compared with common motors, more durable.

4. The perfect combination of the special electric control cabinet, the liquid level floating-ball switch and the protective components carries out the automatic monitor and alarm for water leak and winding overheat, the protections at short circuit, overload, lack-of-phase and voltage-lost cut-off, the accurately auto-controls of start, stop, alternation and minimum submerged depth of the pump, without need of special persons for looking-after, option at will is available between the selfcoupled reducing start and electronic soft start. All of these makes sure of safe and reliable use of the pump without any worry.

5. Both motor and hydraulic parts are directly linked together, without need of turning the shaft for centering, easily disassembled and assembled to save the time, benefit for the site maintenance, reducing the stopped time, saving the cost of repair; simple and compact structure leaves a small volume, only simple lifting equipment is needed, as a special lifting handler is set on the pump; less land area and the pump can be placed directly in the sewage pond, without need of a special pump house, and the therefore the construction investment can be saved by over 40.

6. Available with five installation modes for you to choose: auto-coupled, movable hard-pipe, movable soft-pipe, fixed wet type and fixed dry type installation modes.

The auto-coupled installation means the connection between the pump and the water-out pipeline is made with the water outlet pipe seat of the auto-coupling, without use of the common fasteners, and, when to separate the pump from the water outlet pipe seat, just place it down along with the guide rod and then lift it, simply enough to get free from worry and trouble and save time.

The submersible sewage pump in the fixed dry type installation not only can replace the old vertical sewage pump but also does not fear of flood submersion, so there is no need of a separate flood-proof facility, benefit for lowering the cost of construction.

Both movable hard-pipe and soft-pipe installations, as well as the fixed wet type one, are all the very simple modes of installation.

7. A motor cooling system can be set with the pump, which can not only sufficiently cool the motor but also be helpful for lowering the level of the sewage pond so as to discharge the sewage therein to the utmost degree.

8. The pump works in the submerged mode, so there is no noise problem and benefit for environmental protection.

Technical Data

| Diameter | DN50-800mm |

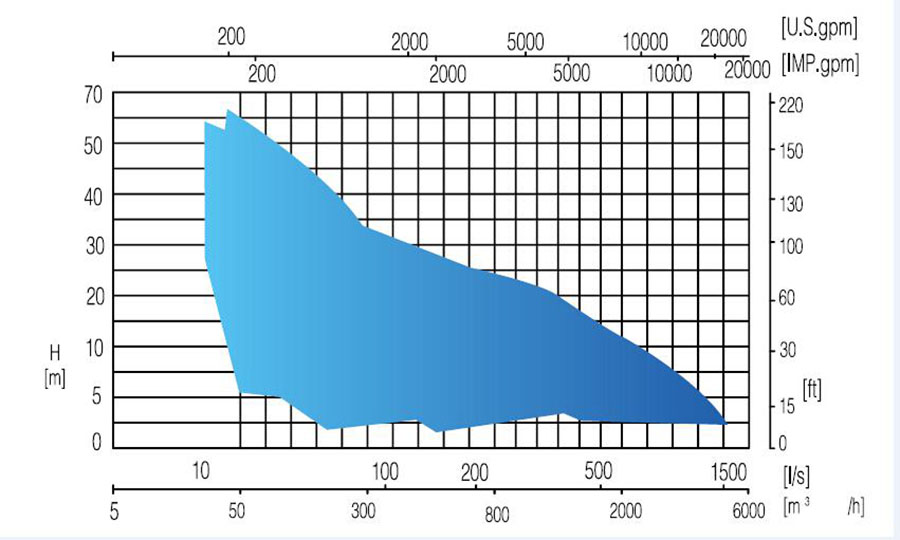

| Capacity | 10-8000 m3/h |

| Head | 3-120m |

| Liquid Temperature | up to 60 ºC |

| Operation pressure | up to 18 bar |

| Part | Material | |

| Pump casing & Pump cover | Cast iron, Ductile iron, Stainless steel | |

| Impeller | Cast iron, Ductile iron, Stainless steel, Bronze, Duplex SS | |

| Motor casing | Cast iron | |

| Shaft | 2Cr13, 3Cr13, Duplex SS | |

| Mechanical seal | Frictional pair | Graphite/ Silicon Carbide Graphite/ Tungsten Carbide Silicon Carbide/Silicon Carbide Silicon Carbide/Tungsten Carbide Tungsten Carbide/Tungsten Carbide |

| Spring | Stainless steel | |

| Rubber part | NBR | |

Technical data

| Flow | 10 - 8,000cbm/h |

| Head | 3 - 120m |

| Medium temperature | 0 ~ 60oC |

| Operation pressure | ≤18bar |

| Diameter | 50 - 800mm |

Application Fields

Municipal works, buildings, industrial sewage.

Sewage treatment to discharge the sewage.

Waste water transfer project.

Rainwater containing solids and long fibers.

Characteristics

1. Lower construction cost.

2. Intelligent control for safe operation.

3. Easy Installation.

4. Submergence resisting.

5. Lower running cost.

6. Environmental protection.

seth@tkflow.com

seth@tkflow.com