What is the use of a VTP pump?

A vertical turbine pump is a type of centrifugal pump that is specifically designed to be installed in a vertical orientation, with the motor located at the surface and the pump submerged in the fluid being pumped. These pumps are commonly used for applications such as water supply, irrigation, cooling water systems, and other industrial and municipal water pumping needs.

The main use of a VTP pump is to lift water or other fluids from a deep well, reservoir, or other water sources to the surface. They are particularly well-suited for applications where the water source is located deep underground and needs to be lifted to the surface for distribution or other purposes. Vertical turbine pumps are also used in applications where a high flow rate and high head (pressure) are required, making them suitable for a wide range of water supply and distribution systems.

Beside water supply applications, vertical turbine pumps are also used in industrial settings for transferring various liquids, including chemicals, petroleum products, and other fluids. Their vertical design allows for efficient use of space and can be customized to meet specific performance requirements for different applications.

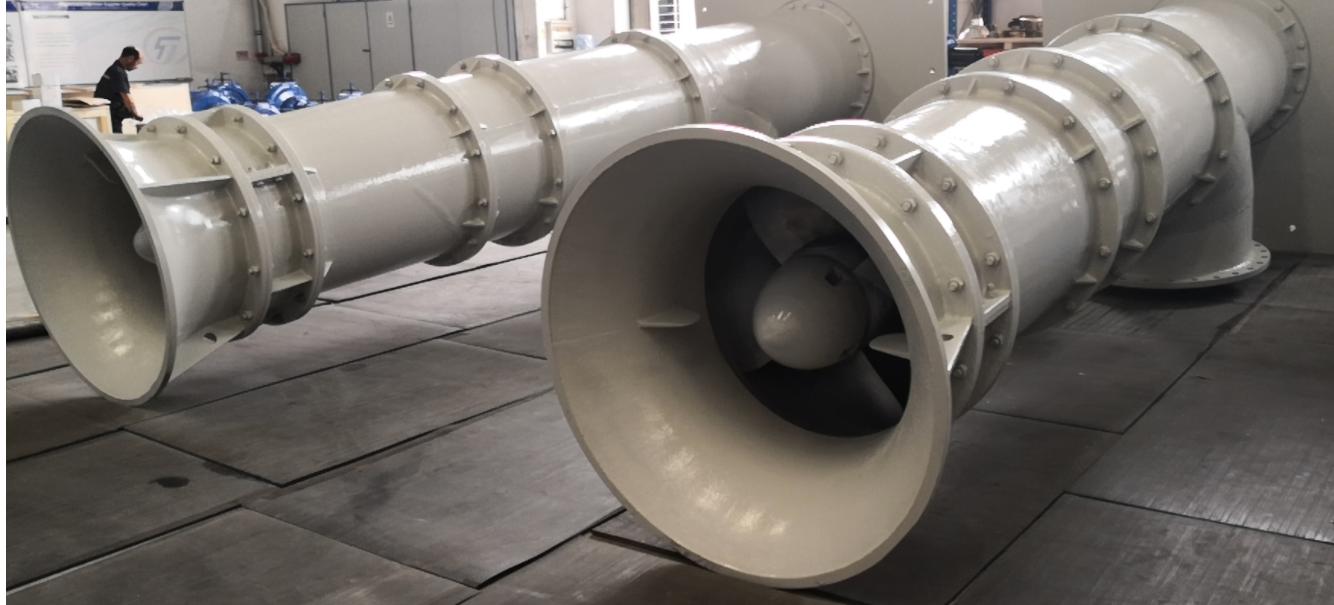

TKFLO VTP Series Vertical Mix Flow Pump

VTP vertical axial-(mixed)-flow pump is a new general-elation product successfully developed by TKFLO by means of introducing the advanced foreign and domestic know how and meticulous designing on the basis of the requirements from users and the conditions of use. This series product uses the latest excellent hydraulic model, wide range of high efficacy, stable performance and good vapor erosion resistance; the impeller is precisely cast with a wax mould, a smooth and unimpeded surface, identical accuracy of the cast dimension to that in design, greatly reduced hydraulic friction loss and shocking loss, a better balance of impeller, a higher efficiency than that of the common impellers by 3-5%.

What Does Shaft Mean In Pump?

In the context of a pump, the term "shaft" typically refers to the rotating component that transmits power from the motor to the impeller or other rotating parts of the pump. The shaft is responsible for transferring the rotational energy from the motor to the impeller, which then creates the necessary flow and pressure to move the fluid through the pump.

The shaft in a pump is usually a solid, cylindrical metal component that is designed to be strong and durable, as it needs to withstand the torque and rotational forces generated during the pumping process. It is often supported by bearings to ensure smooth rotation and minimize friction.

In some pump designs, the shaft may also be connected to other components such as seals, couplings, or drive mechanisms, depending on the specific type and configuration of the pump.

Long-shaft pump (Deep-well pump) usage

A long-shaft pump, also known as a deep-well pump, is designed for applications where the water source is located deep underground, such as in a well or borehole.

These pumps are specifically designed to handle the challenges of lifting water from considerable depths, often exceeding the capabilities of traditional pumps. The long shaft allows the pump to reach the water source at depth and bring it to the surface for distribution or other uses.

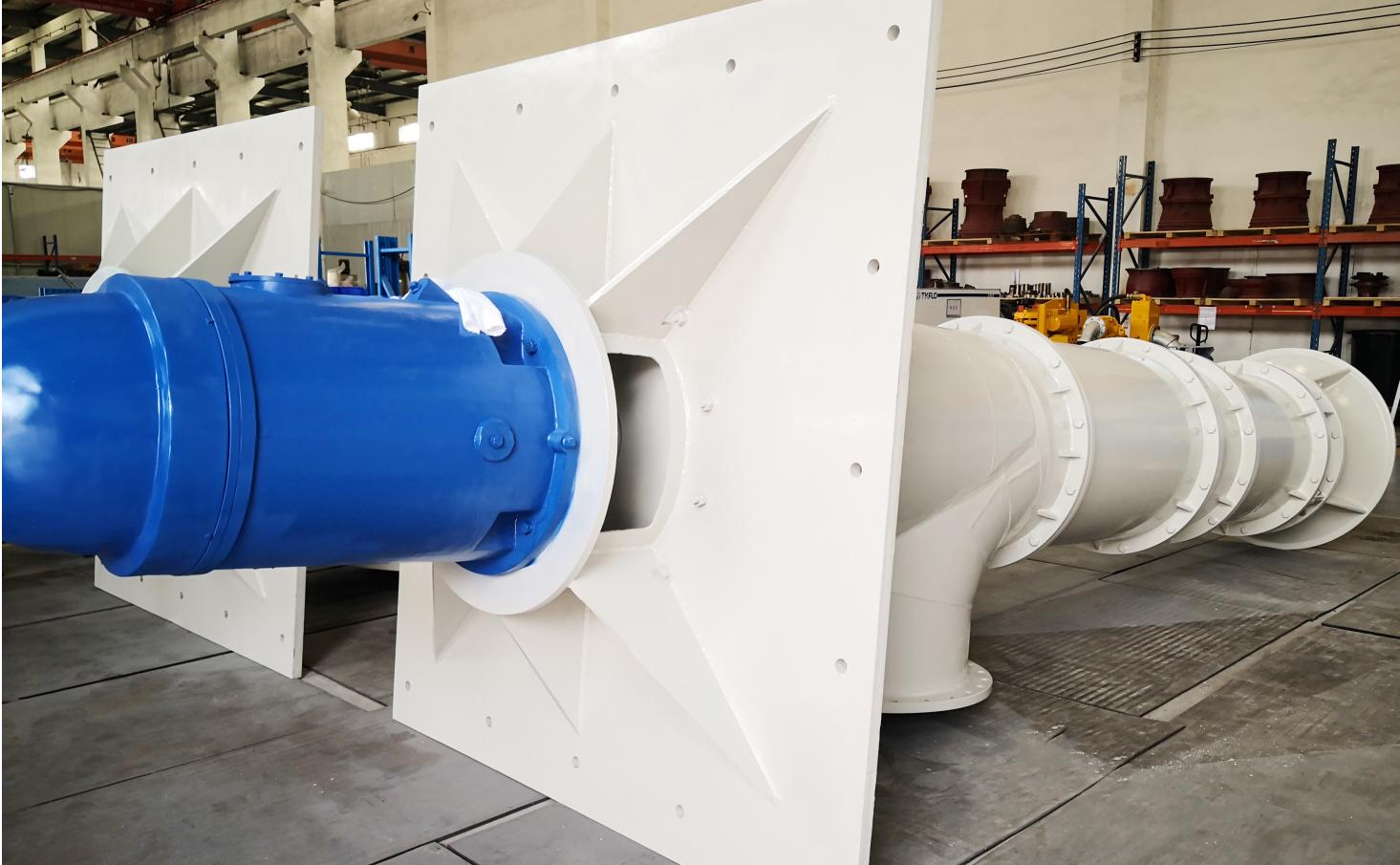

TKFLO AVS series Vertical Axial Flow And MVS series Mixed Flow Submersible Sewage Pump

MVS series axial-flow pumps AVS series mixed-flow pumps (Vertical Axial flow and Mixed flow submersible sewage pump) are modern productions successfully designed by the means of adopting foreign modern technology. The new pumps’ capacity are 20%larger than the old ones. The efficiency is 3~5% higher than the old ones.

Post time: Aug-08-2024