What Is The NFPA For Fire Water Pump

The National Fire Protection Association (NFPA) has several standards that pertain to fire water pumps, primarily NFPA 20, which is the “Standard for the Installation of Stationary Pumps for Fire Protection.” This standard provides guidelines for the design, installation, and maintenance of fire pumps used in fire protection systems.

Key points from NFPA 20 include:

Types of Pumps:

It covers various types of fire fighting pumps, including centrifugal pumps, positive displacement pumps, and others.

Installation Requirements:

It outlines requirements for the installation of fire pumps, including location, accessibility, and protection from environmental factors.

Testing and Maintenance:

NFPA 20 specifies testing protocols and maintenance practices to ensure that fire pumps operate effectively when needed.

Performance Standards:

The standard includes performance criteria that fire pumps must meet to ensure adequate water supply and pressure for firefighting operations.

Power Supply:

It addresses the need for reliable power sources, including backup systems, to ensure that fire pumps can operate during emergencies.

From nfpa.org, it states NFPA 20 protects life and property by providing requirements for the selection and installation of pumps to ensure that systems will work as intended to deliver adequate and reliable water supplies in a fire emergency.

How To Calculate Fire Water Pump Pressure?

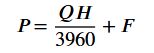

To calculate fire pump pressure, you can use the following formula:

Formula:

Where:

· P = Pump pressure in psi (pounds per square inch)

· Q = Flow rate in gallons per minute (GPM)

· H = Total dynamic head (TDH) in feet

· F = Friction loss in psi

Steps to Calculate Fire Pump Pressure:

Determine Flow Rate (Q):

· Identify the required flow rate for your fire protection system, usually specified in GPM.

Calculate Total Dynamic Head (TDH):

· Static Head: Measure the vertical distance from the water source to the highest point of discharge.

· Friction Loss: Calculate the friction loss in the piping system using friction loss charts or formulas (like the Hazen-Williams equation).

· Elevation Loss: Account for any elevation changes in the system.

[TDH= Static Head + Friction Loss + Elevation Loss]

Calculate Friction Loss (F):

· Use the appropriate formulas or charts to determine the friction loss based on the pipe size, length, and flow rate.

Plug Values into the Formula:

· Substitute the values of Q, H, and F into the formula to calculate the pump pressure.

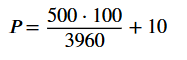

Example Calculation:

· Flow Rate (Q): 500 GPM

· Total Dynamic Head (H): 100 feet

· Friction Loss (F): 10 psi

Using the formula:

Important Considerations:

· Ensure that the calculated pressure meets the requirements of the fire protection system.

· Always refer to NFPA standards and local codes for specific requirements and guidelines.

· Consult with a fire protection engineer for complex systems or if you’re unsure about any calculations.

How Do You Check Fire Pump Pressure?

To check fire pump pressure, you can follow these steps:

1. Gather Necessary Equipment:

Pressure Gauge: Ensure you have a calibrated pressure gauge that can measure the expected pressure range.

Wrenches: For connecting the gauge to the pump or piping.

Safety Gear: Wear appropriate safety gear, including gloves and goggles.

2. Locate the Pressure Test Port:

Identify the pressure test port on the fire pump system. This is usually located on the discharge side of the pump.

3. Connect the Pressure Gauge:

Use the appropriate fittings to connect the pressure gauge to the test port. Ensure a tight seal to prevent leaks.

4. Start the Fire Pump:

Turn on the fire pump according to the manufacturer’s instructions. Ensure that the system is primed and ready for operation.

5. Observe the Pressure Reading:

Once the pump is running, observe the pressure reading on the gauge. This will give you the discharge pressure of the pump.

6. Record the Pressure:

Note the pressure reading for your records. Compare it to the required pressure specified in the system design or NFPA standards.

7. Check for Variations:

If applicable, check the pressure at different flow rates (if the system allows) to ensure the pump operates effectively across its range.

8. Shut Down the Pump:

After testing, safely shut down the pump and disconnect the pressure gauge.

9. Inspect for Issues:

After testing, inspect the system for any leaks or abnormalities that may need attention.

Important Considerations:

Safety First: Always follow safety protocols when working with fire pumps and pressurized systems.

Regular Testing: Regular pressure checks are essential for maintaining the reliability of the fire pump.

What Is The Minimum Residual Pressure For Fire Pump?

The minimum residual pressure for fire pumps typically depends on the specific requirements of the fire protection system and local codes. However, a common standard is that the minimum residual pressure should be at least 20 psi (pounds per square inch) at the most remote hose outlet during maximum flow conditions.

This ensures that there is adequate pressure to effectively deliver water to the fire suppression system, such as sprinklers or hoses.

Horizontal split casing centrifugal pumps complies with NFPA 20 and UL listed application requirements and with appropriate fittings for providing water supply to fire protection systems in buildings, factories plants and yards.

| scope of supply : Engine drive fire pump+ control panel+ Jockey pump / Electrical motor drive pump + control panel+ Jockey pump |

|

Other request for the unit please discuses with TKFLO engineers. |

|

Type of Pump |

Horizontal centrifugal pumps with appropriate fitting for providing water supply to fire protection system in buildings, plants and yards. |

|

Capacity |

300 to 5000GPM (68 to 567m3/hr) |

|

Head |

90 to 650 feet (26 to 198 meters) |

|

Pressure |

Up to 650 feet (45 kg/cm2, 4485 KPa) |

|

House Power |

Up to 800HP (597 KW) |

|

Drivers |

Vertical electrical motors and diesel engines with right angle gears, and steam turbines. |

|

Liquid type |

Water or sea water |

|

Temperature |

Ambient within the limits for satisfactory equipment operation. |

|

Material of Construction |

Cast iron, Bronze fitted as standard. Optional materials available for sea water applications. |

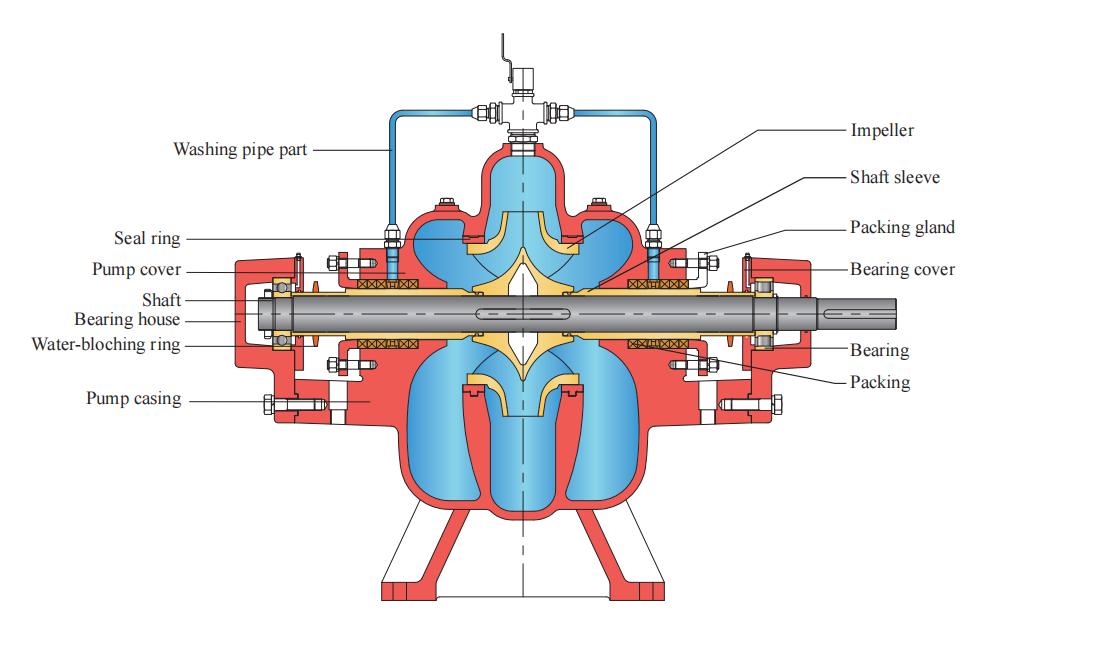

SECTION VIEW of Horizontal Split Casing Centrifugal Fire Pump

Post time: Oct-28-2024