In fire protection systems, the effective management of water pressure and flow is crucial for ensuring safety and compliance with fire codes. Among the key components of these systems are jockey pumps and main pumps. While both serve essential roles, they operate under different conditions and fulfill distinct functions. This article explores the differences between jockey pumps and main pumps, highlighting their specific applications, operational characteristics, and the importance of each in maintaining optimal fire protection.

The main pump is the primary pump responsible for supplying the necessary water flow to the fire protection system. It is designed to deliver high volumes of water during a fire event, typically operating continuously until the fire is extinguished. Main pumps are critical in ensuring that water is available to fire hydrants, sprinklers, and standpipes.

Main pumps generally have larger capacities, often rated from several hundred to thousands of gallons per minute (GPM), and operate at lower pressures during normal conditions. They are activated when the fire alarm system detects a need for water flow.

They are utilized during fire emergencies to deliver water at high flow rates, ensuring that the system can effectively combat fires.

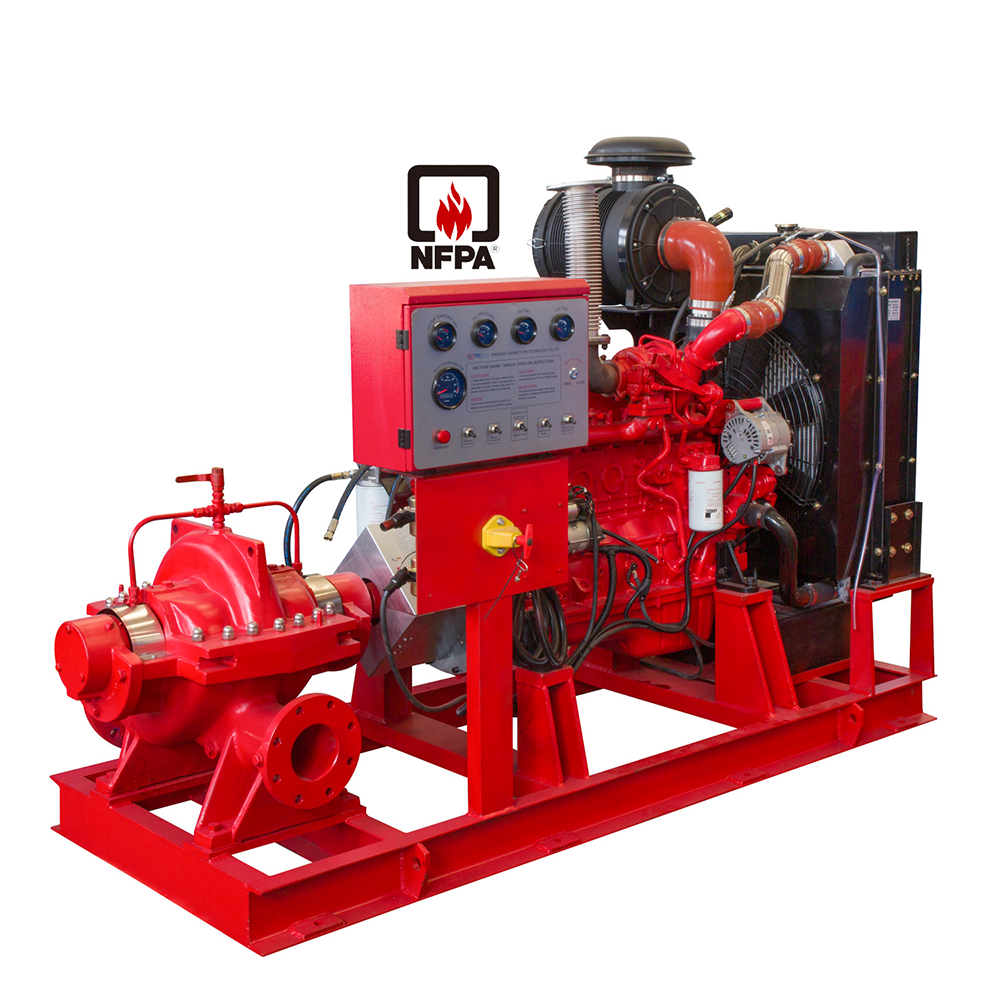

NFPA 20 Diesel Engine Drive Split Casing Double Suction Centrifugal Fire Water Pump Set

Model No:ASN

Precision balancing of all factors in the design of ASN horizontal split case fire pump provide mechanical dependability, efficient operation and minimal maintenance. Simplicity of design ensures long efficient unit life, reduced maintenance costs and minimum power consumption.Split case fire pumps are specifically designed and tested for fire service application around the world including: Office buildings, hospitals, airports, manufacturing facilities, warehouses, power stations, oil and gas industry, schools.

In contrast, the jockey pump is a smaller pump designed to maintain the pressure in the fire protection system when there is no significant water demand. It operates automatically to compensate for minor leaks or fluctuations in the system, ensuring that the pressure remains within a predetermined range.

Jockey pumps typically operate at higher pressures but at lower flow rates, usually between 10 to 25 GPM. They cycle on and off as needed to maintain system pressure, ensuring that the main pump is not activated unnecessarily.

TKFLO Jockey water pumps play a preventive role, keeping the system pressurized during idle periods, thus reducing wear and tear on the main pump and preventing damage from pressure fluctuations.

Multistage Centrifugal High Pressure Stainless Steel Jockey Pump Fire Water Pump

Model No:GDL

GDL Vertical fire Pump with control panel is the latest model, energy-saving, less space demand, easy to install and stable performance.(1) With its 304 stainless steel shell and wear-resistant axle seal, it is no leakage and long service life.(2) With hydraulic equilibrium to balance the axial force, the pump can run more smoothly, less noise and, which can be easily installed in the pipeline which is on the same level, enjoying better installation conditions than DL model.(3) With these features, GDL Pump can easily meet the needs and requirements for water supply and drain for high building, deep well and firefighting equipments.

The integration of smart technology in both jockey and main pumps is becoming increasingly common. Monitoring systems can provide real-time data on performance metrics, alerting operators to potential issues before they escalate, thereby enhancing system reliability and efficiency.

understanding the differences between jockey pumps and main pumps is essential for effective fire protection system design and maintenance. Main pumps are crucial for delivering large volumes of water during emergencies, while jockey pumps ensure that the system remains pressurized and ready for action. By recognizing the unique functions and operational characteristics of each type of pump, fire protection professionals can better design, implement, and maintain systems that meet safety standards and optimize performance. As technology continues to advance, staying informed about the latest developments will be vital for ensuring the reliability and efficiency of fire protection systems.

Post time: Nov-15-2024

seth@tkflow.com

seth@tkflow.com