What Is a Wellpoint Pump? Key Components Of a Wellpoint Dewatering System Explained

There are several different types of well pumps, each designed for specific applications and conditions. Here are some of the most common types of well pumps:

1. Jet Pumps

Jet pumps are commonly used for shallow wells and can also be adapted for deeper wells with the use of a two-pipe system.

Shallow Well Jet Pumps: These are used for wells with depths up to about 25 feet. They are installed above ground and use suction to draw water from the well.

Deep Well Jet Pumps: These can be used for wells with depths up to about 100 feet. They use a two-pipe system to create a vacuum that helps lift water from deeper levels.

Submersible pumps are designed to be placed inside the well, submerged in water. They are suitable for deeper wells and are known for their efficiency and reliability.

Deep Well Submersible Pumps: These are used for wells that are deeper than 25 feet, often reaching depths of several hundred feet. The pump is placed at the bottom of the well and pushes water to the surface.

Centrifugal pumps are typically used for shallow wells and surface water sources. They are installed above ground and use a rotating impeller to move water.

Single-Stage Centrifugal Pumps: Suitable for shallow wells and applications where the water source is close to the surface.

Multi-Stage Centrifugal Pumps: Used for applications requiring higher pressure, such as irrigation systems.

4. Hand Pumps

Hand pumps are manually operated and are often used in remote or rural areas where electricity is not available. They are suitable for shallow wells and are simple to install and maintain.

5. Solar-Powered Pumps

Solar-powered pumps use solar panels to generate electricity, making them ideal for remote locations and areas with abundant sunlight. They can be used for both shallow and deep wells.

Wellpoint pumps are specifically designed for dewatering applications in construction and civil engineering. They are used to lower groundwater levels and control water tables in shallow excavations.

Vacuum-Assisted Wellpoint Pumps: These pumps create a vacuum to draw water from wellpoints and are effective for shallow dewatering applications.

How deep is a wellpoint?

A wellpoint is typically used for shallow dewatering applications and is generally effective at depths of up to 5 to 7 meters (approximately 16 to 23 feet). This depth range makes wellpoints suitable for controlling groundwater levels in relatively shallow excavations, such as those found in foundation construction, trenching, and utility installations.

The effectiveness of a wellpoint system can be influenced by various factors, including soil type, groundwater conditions, and the specific requirements of the dewatering project. For deeper dewatering needs, other methods such as deep wells or boreholes may be more appropriate.

What is the difference between a borehole and a well point?

The terms “borehole” and “wellpoint” refer to different types of wells used for various purposes, including water extraction and dewatering. Here are the key differences between the two:

Borehole

Depth: Boreholes can be drilled to significant depths, often ranging from tens to hundreds of meters, depending on the purpose and geological conditions.

Diameter: Boreholes typically have a larger diameter compared to wellpoints, allowing for the installation of larger pumps and greater water extraction capacity.

Purpose: Boreholes are primarily used for extracting groundwater for drinking water, irrigation, industrial use, and sometimes for geothermal energy extraction. They can also be used for environmental monitoring and sampling.

Construction: Boreholes are drilled using specialized drilling rigs. The process involves drilling a hole into the ground, installing a casing to prevent collapse, and placing a pump at the bottom to lift water to the surface.

Components: A borehole system usually includes a drilled hole, casing, screen (to filter out sediments), and a submersible pump.

Wellpoint

Depth: Wellpoints are used for shallow dewatering applications, generally up to depths of around 5 to 7 meters (16 to 23 feet). They are not suitable for deeper groundwater control.

Diameter: Wellpoints have a smaller diameter compared to boreholes, as they are designed for shallow and closely spaced installations.

Purpose: Wellpoints are primarily used for dewatering construction sites, lowering groundwater levels, and controlling water tables to create dry and stable working conditions in excavations and trenches.

Construction: Wellpoints are installed using a jetting process, where water is used to create a hole in the ground, and the wellpoint is then inserted. Multiple wellpoints are connected to a header pipe and a Wellpoint pump that creates a vacuum to draw water from the ground.

Components: A wellpoint system includes small-diameter wellpoints, a header pipe, and a Wellpoint pump (often a centrifugal or piston pump).

What is the difference between well point and deep well?

Wellpoint System

Depth: Wellpoint systems are typically used for shallow dewatering applications, generally up to depths of around 5 to 7 meters (16 to 23 feet). They are not suitable for deeper groundwater control.

Components: A wellpoint system consists of a series of small-diameter wells (wellpoints) connected to a header pipe and a Wellpoint pump. The wellpoints are usually spaced closely together around the perimeter of the excavation site.

Installation: Wellpoints are installed using a jetting process, where water is used to create a hole in the ground, and the wellpoint is then inserted. The wellpoints are connected to a header pipe, which is connected to a vacuum pump that draws water from the ground.

Applications: Wellpoint systems are ideal for dewatering in sandy or gravelly soils and are commonly used for shallow excavations, such as foundation construction, trenching, and utility installations.

Deep Well System

Depth: Deep well systems are used for dewatering applications that require groundwater control at greater depths, typically beyond 7 meters (23 feet) and up to 30 meters (98 feet) or more.

Components: A deep well system consists of larger-diameter wells equipped with submersible pumps. Each well operates independently, and the pumps are placed at the bottom of the wells to lift water to the surface.

Installation: Deep wells are drilled using drilling rigs, and the submersible pumps are installed at the bottom of the wells. The wells are usually spaced farther apart compared to wellpoints.

Applications: Deep well systems are suitable for dewatering in a variety of soil types, including cohesive soils like clay. They are commonly used for deeper excavations, such as large-scale construction projects, mining operations, and deep foundation work.

What is a Wellpoint pump?

A Wellpoint pump is a type of dewatering pump used primarily in construction and civil engineering to lower groundwater levels and control water tables. This is essential for creating dry and stable working conditions in excavations, trenches, and other below-ground projects.

The Wellpoint system typically consists of a series of small-diameter wells, known as wellpoints, which are installed around the perimeter of the excavation site. These wellpoints are connected to a header pipe, which in turn is connected to the Wellpoint pump. The pump creates a vacuum that draws water up from the wellpoints and discharges it away from the site.

Key components of a Wellpoint dewatering system include:

Wellpoints: Small-diameter pipes with a perforated section at the bottom, which are driven into the ground to collect groundwater.

Header Pipe: A pipe that connects all the wellpoints and channels the collected water to the pump.

Wellpoint Pump: A specialized pump, often a centrifugal or piston pump, designed to create a vacuum and remove water from the wellpoints.

Discharge Pipe: A pipe that carries the pumped water away from the site to a suitable discharge location.

Wellpoint pumps are particularly effective in sandy or gravelly soils where groundwater can be easily drawn through the wellpoints. They are commonly used in applications such as:

Foundation construction

Pipeline installation

Sewer and utility trenching

Road and highway construction

Environmental remediation projects

By lowering the groundwater level, Wellpoint pumps help to stabilize the soil, reduce the risk of flooding, and create safer and more efficient working conditions.

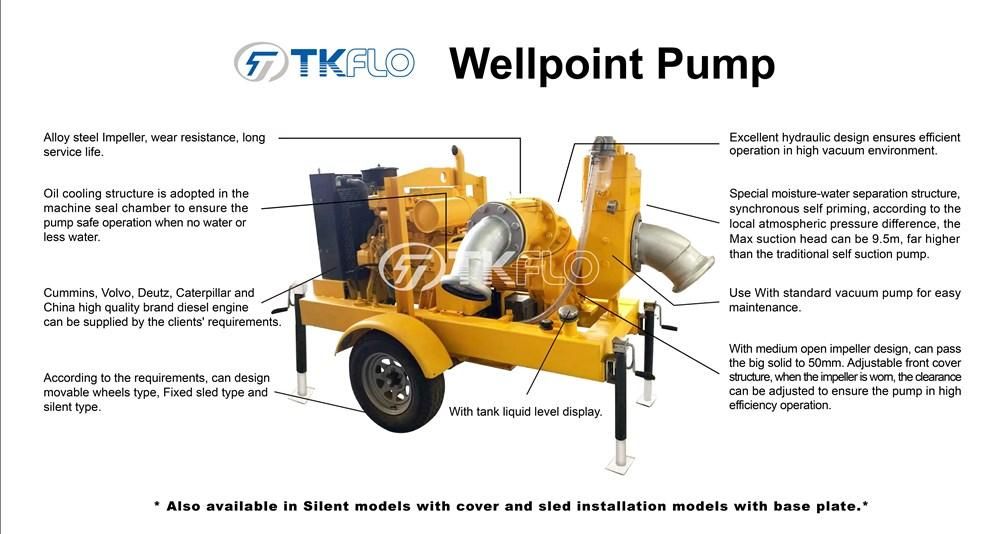

TKFLO Mobile Two Treys Diesel Engine Drive Vacuum Priming Well Point Pump

Model No:TWP

TWP series Movable Diesel Engine self-priming Well point Water Pumps for emergency are joint designed by DRAKOS PUMP of Singapore and REEOFLO company of Germany . This series of pump can transport all kinds of clean, neutral and corrosive medium containing particles. Solve a lot of traditional self-priming pump faults. This kind of self-priming pump unique dry running structure will be automatic startup and restart without liquid for first start, The suction head can be more than 9 m; Excellent hydraulic design and unique structure keep the high efficiency more than 75%. And different structure installation for optional.

Post time: Sep-14-2024