What Are The Three Major Types Of Fire Pumps?

The three major types of fire pumps are:

1. Split case Centrifugal pumps: These pumps use centrifugal force to create a high-velocity flow of water. Split case pumps are commonly used in fire-fighting applications due to their reliability and efficiency. They have a split casing design, which allows for easy access to the internal components for maintenance and repair. Spit casing pumps are known for their ability to deliver high flow rates and maintain consistent pressure, making them suitable for supplying water to fire suppression systems, fire hydrants, and fire trucks.

Split case pumps are often used in large industrial and commercial buildings, as well as in municipal fire-fighting systems. They are designed to handle high-capacity water flow and are typically driven by electric motors or diesel engines. The split case design also allows for easy installation and maintenance, making them a popular choice for fire-fighting applications.

2. Positive displacement pumps: These pumps use a mechanism to displace a specific volume of water with each cycle. They are often used in fire-fighting vehicles and portable fire pumps due to their ability to maintain pressure and flow rate even at high pressures.

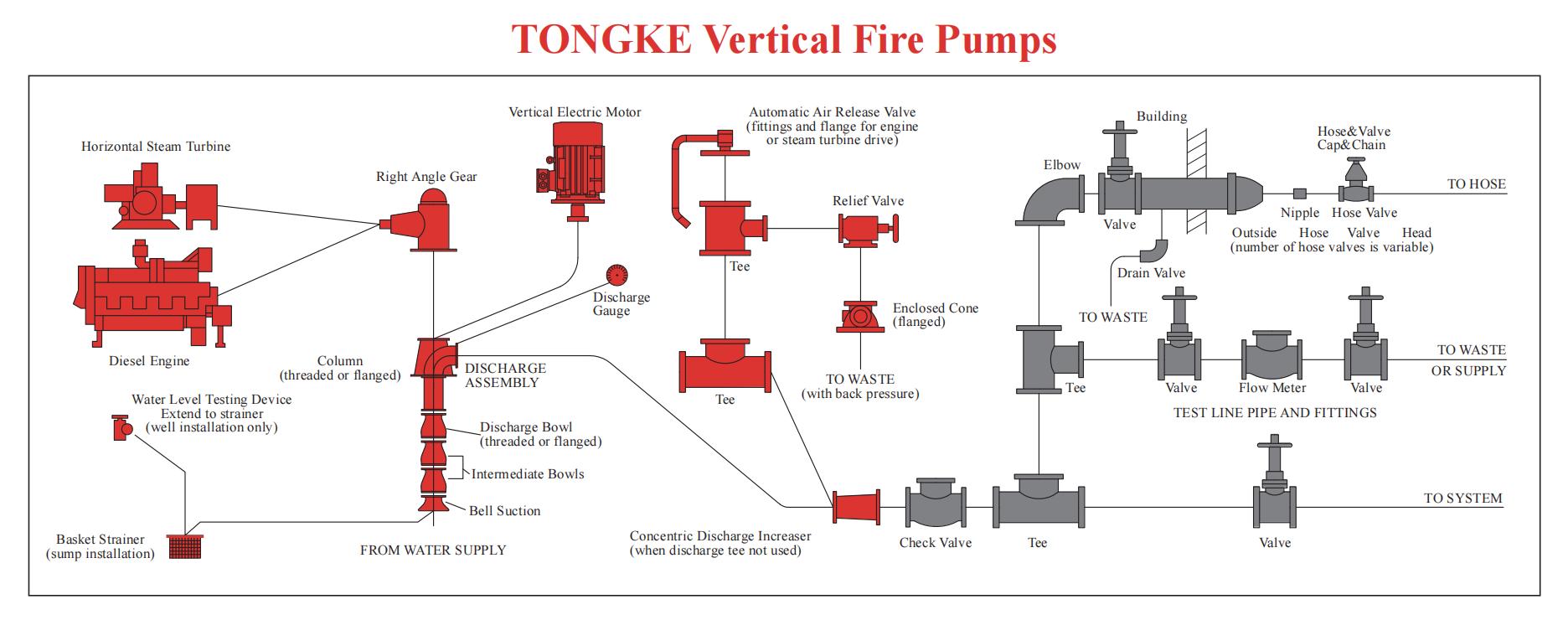

3.Vertical turbine pumps: These pumps are often used in high-rise buildings and other structures where a high-pressure water supply is needed. They are designed to operate efficiently in deep wells and can provide a reliable source of water for fire-fighting systems in tall buildings.

Each type of fire pump has its own advantages and is suitable for different fire-fighting scenarios.

TKFLO Double Suction Split Casing Centrifugal Pumps for Fire Fighting

Model No:XBC-VTP

XBC-VTP Series vertical long shaft fire fighting pumps are series of single stage, multistage diffusers pumps, manufactured in accordance with the latest National Standard GB6245-2006. We also improved the design with the reference of the standard of United States Fire Protection Association. It is mainly used for fire water supply in petrochemical, natural gas, power plant, cotton textile, wharf, aviation, warehousing, high-rising building and other industries. It can also apply to ship, sea tank, fire ship and other supply occasions.

Can you use a transfer pump for fire-fighting?

Yes, transfer pumps can be used for fire-fighting purposes.

The main difference between a transfer pump and a fire-fighting pump lies in their intended use and design features:

Intended Use:

Transfer Pump: A transfer pump is primarily used to move water or other fluids from one location to another. It is commonly employed for tasks such as draining water from a flooded area, transferring water between containers, or filling tanks.

Fire-Fighting Pump: A fire-fighting pump is specifically designed to supply water at high pressure and flow rates for fire suppression systems. It is intended for use in emergency situations to provide water to fire sprinklers, hydrants, hoses, and other fire-fighting equipment.

Design Features:

Transfer Pump: Transfer pumps are typically designed for general-purpose fluid transfer and may not be optimized for the high-pressure, high-flow requirements of fire-fighting applications. They may have a more versatile design suitable for a range of fluid-handling tasks.

Fire-Fighting Pump: Fire-fighting pumps are engineered to meet strict performance and safety standards for fire suppression. They are designed to deliver the necessary pressure and flow rates required to combat fires effectively, often featuring robust construction and specialized components to withstand demanding conditions.

So,transfer pumps are often used to move water from one location to another, and in the case of fire-fighting, they can be used to transfer water from a water source, such as a pond or a hydrant, to a fire truck or directly to the fire. This can be especially useful in situations where access to water is limited or where traditional fire hydrants are not available.

What makes a fire fighting pump different from other kinds of pumps?

Fire pump is specifically designed and built to meet the unique requirements of fire-fighting applications.

They are mandated to achieve specific flow rates (GPM) and pressures of 40 PSI or higher. Additionally, the aforementioned agencies recommend that the pumps maintain at least 65% of that pressure at 150% of the rated flow, all while operating under a 15-foot lift condition. The performance curves must be tailored to ensure that the shut-off head, or “churn,” falls within the range of 101% to 140% of the rated head, in accordance with the specific definitions provided by the regulatory agencies. TKFLO’s fire pumps are only offered for fire pump service after meeting all the stringent requirements set by these agencies.

Beyond performance characteristics, TKFLO fire pumps undergo thorough scrutiny by both U.L. and F.M. to ensure reliability and longevity through a comprehensive analysis of their design and construction. For instance, the casing integrity must be capable of withstanding a hydrostatic test at three times the maximum operating pressure without bursting. TKFLO’s compact and well-engineered design enables compliance with this specification across many of our 410 and 420 models. Furthermore, engineering calculations for bearing life, bolt stress, shaft deflection, and shear stress are meticulously evaluated by U.L. and F.M. to ensure that they fall within conservative limits, thereby guaranteeing utmost reliability. The superior design of TKFLO’s split-case line consistently meets and exceeds these stringent requirements.

Upon meeting all preliminary requirements, the pump undergoes final certification testing, which is witnessed by representatives from U.L. and F.M. Performance tests are conducted to demonstrate the satisfactory operation of several impeller diameters, including the minimum and maximum, as well as several intermediate sizes.

Post time: Aug-26-2024