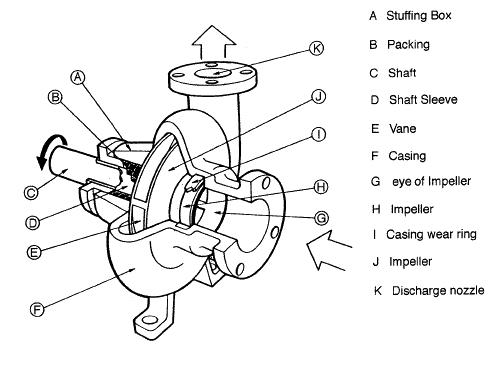

A standard centrifugal pump requires the following components to function properly:

1. Impeller

2. Pump Casing

3. Pump Shaft

4. Bearings

5. Mechanical Seal,Packing

Impeller

The impeller is the core part of a centrifugal pump, and the blades on the impeller play a major role. Before assembly, the impeller needs to undergo static balance experiments. The inner and outer surfaces of the impeller are required to be smooth to reduce friction losses caused by water flow.

Pump Casing

The pump casing, is the main body of the water pump. Plays a supporting and fixing role, and is connected to the bracket for installing bearings.

Pump Shaft

The function of the pump shaft is to connect the coupling with the electric motor, transmitting the torque of the electric motor to the impeller, so it is the main component for transmitting mechanical energy.

Bearing

The sliding bearing uses transparent oil as a lubricant and is filled to the oil level line. Too much oil will seep out along the pump shaft, and too little bearing will overheat and burn out, causing accidents! During the operation of the water pump, the highest temperature of the bearings is 85 degrees, and generally operates at around 60 degrees.

Mechanical Seal , Packing

The mechanical seal or packing are crucial pump components designed to keep the liquid being contained inside the casing from leaking out along the rotating shaft. The mechanical seal or packing are housed within the casing cover that forms the back of the casing. Various types of sealing arrangements can be used depending on process variables. Crucial criteria to consider before selecting a mechanical seal or packing include:The nature of process fluid to be pumped

The pump’s operational temperature and pressure

Centrifugal Pump Diagram

The diagram above shows the essential components of centrifugal pump system.

More details please click the link:

Post time: Dec-07-2023

seth@tkflow.com

seth@tkflow.com