The vertical pump motor transformed the pumping industry in the early 1920s by enabling the attachment of electric motors to the top of a pump, resulting in significant impacts. This simplified the installation process and reduced costs due to the requirement of fewer parts. The efficiency of pump motors increased by 30%, and the purpose-specific nature of vertical pump motors made them more durable and reliable compared to their horizontal counterparts.

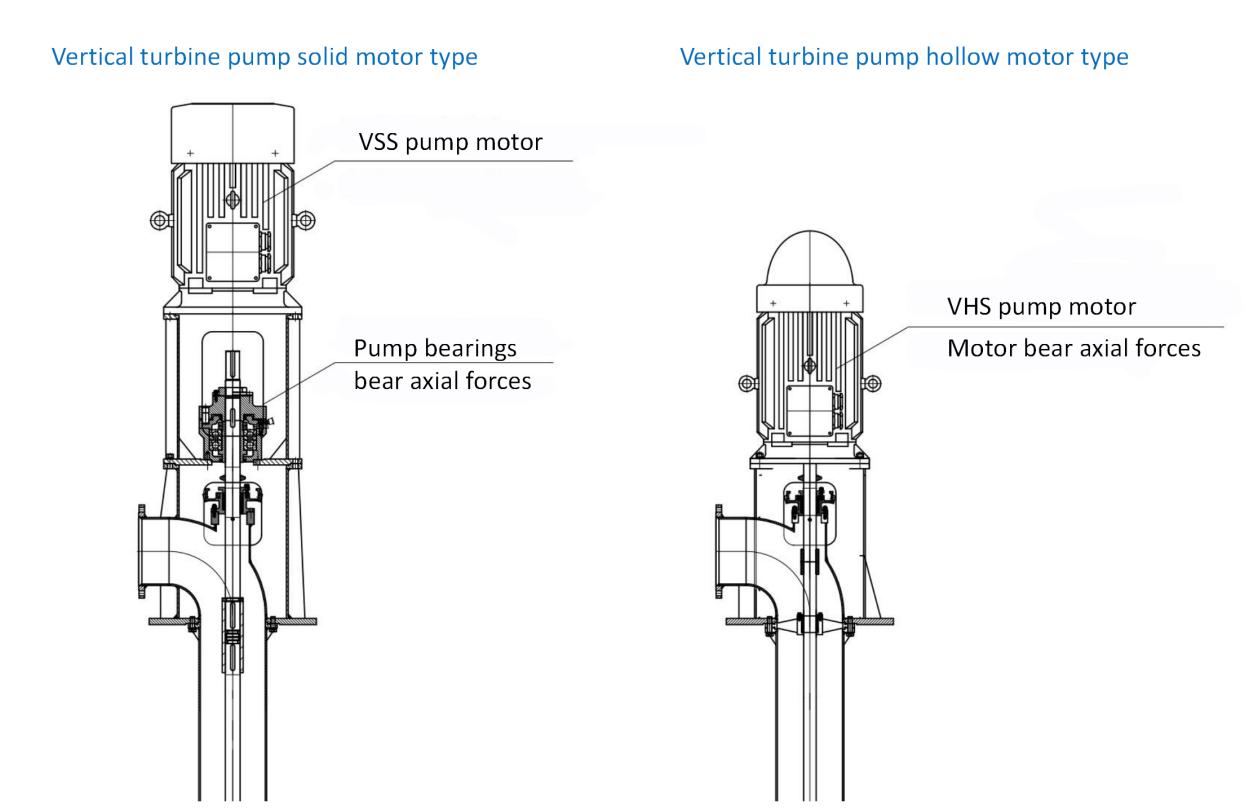

Vertical pump motors are typically categorized based on their shaft type, either hollow or solid.

Vertical hollow shaft (VHS) pump motors and vertical solid shaft (VSS) pump motors have several differences in their design and application. Here are some of the key differences:

1. Shaft Design:

- VHS pump motors have a hollow shaft, which allows the pump shaft to pass through the motor for direct connection to the impeller. This design eliminates the need for a separate coupling and reduces the overall length of the pump-motor assembly.

- VSS pump motors have a solid shaft that extends from the motor to the impeller. The shaft extension usually features a circular keyway for transmitting pump thrust and a radial keyway for transferring torque. The lower end coupling between the pump motor and the pump shaft is commonly observed in tanks and shallow pumps, as opposed to deep-well operations.

2. Application:

- VHS pump motors are commonly used in deep well and submersible pump applications where the pump shaft extends into the well or sump.

- VSS pump motors are often used in applications where the pump shaft does not need to extend into the well or sump, such as in-line pumps or applications where the pump is located above the water level.

3. Maintenance:

- VHS pump motors may be easier to maintain and service due to the direct connection between the motor and pump shaft. However, accessing the motor for maintenance may be more challenging due to its location in the well or sump.

- VSS pump motors may require more frequent maintenance of the coupling between the motor and pump shaft, but the motor itself may be more accessible for servicing.

About Vertical Hollow Shaft Motors: What Are Hollow Motors For?

Vertical hollow shaft (VHS) motors are designed for specific applications where the pump shaft extends into the well or sump.

Originally, above-ground pumps were utilized for irrigation in dry yet agriculturally favorable climates, such as California. These pumps featured right-angle gear configurations and were powered by internal combustion engines. The introduction of electric motors atop the pumps eliminated the necessity for a mechanical gearbox to provide torque and external thrust bearings for additional pump thrust. This reduction in equipment resulted in lower costs, smaller size, easier installation, and fewer parts. Vertical pump motors also operate approximately 30% more efficiently than horizontal motors and are specifically designed for the job, offering increased durability and reliability for pump applications. Furthermore, they are engineered to withstand a wider variety of environmental conditions. As a result, farming in California was able to thrive under these conditions.

Should I Choose Solid Shaft Motor Or Hollow Shaft Motor To Do The Job

Choosing the right solid shaft motor or hollow shaft motor for a specific job depends on the application requirements and environmental conditions. Solid shaft motors are typically used in applications where the pump shaft does not need to extend into the well or sump, such as in-line pumps or above-ground installations. On the other hand, hollow shaft motors are suitable for deep well and submersible pump applications, where the pump shaft extends into the well or sump.

In addition to the standard specifications such as horsepower, speed, enclosure, input power, and frame size that are associated with all induction motors, vertical hollow shaft (VHS) motors also have specific thrust requirements. The thrust capacity of the motor must exceed the total axial forces it will encounter, including the weight of the rotor, the pump line shaft and impeller, and the dynamic forces required to lift the liquid to the surface.

There are three options or the thrust: normal thrust motors, medium thrust motors, and high thrust motors. A horizontal motor is considered a normal thrust motor and is suitable for general applications where minimal external thrust is applied to the motor bearing.

A medium thrust motor, also known as an in-line pump motor, is designed for specific operations and is considered a definite purpose motor. The impellers are directly mounted on the motor shaft, and the thrust bearing is typically located at the bottom to prevent the rotor's thermal growth from impacting the impeller clearances. Tighter motor shaft and flange run-out tolerances are required, as the impeller performance depends on close tolerance with the pump housing.

A high thrust motor can be highly customizable by the manufacturer and commonly offers thrusts of 100%, 175%, or 300%, with the thrust bearing usually located near the top.

If you need assistance in selecting the right motor for your job, do not hesitate to contact a professional at Tkflo. We are happy to address any questions you may have about choosing the appropriate vertical hollow shaft motor based on your specific needs.

What Are The Applications For The Vertical Turbine Pumps?

The applications for Vertical Turbine Pumps include various uses in water supply, irrigation, industrial processes, and municipal water systems. They are utilized for agricultural irrigation, water transfer in municipal water supply systems, and industrial processes such as cooling water circulation and wastewater treatment.

Vertical turbine pump (VTP) is a form of rotary power pump featuring a radial or improved radial flow impeller. These pumps are usually multistage, incorporating multiple impeller levels within a bowl assembly, and can be categorized as either deep well pumps or short set pumps.

A deep-well turbine is commonly installed in a drilled well, with the initial stage impeller positioned below the water level of the pump. These pumps are self-priming, typically comprising a multistage assembly, and are primarily utilized for water conveyance. Their main application involves transporting water from deep wells to the surface.

These pumps convey water to treatment plants, irrigation systems, and household faucets. Short-set pumps function similarly to deep-well pumps, operating in shallow water sources with a maximum depth of around 40 ft.

VTP pump can be installed in a suction barrel or below ground level to increase the suction heads for the first stage impeller. These pumps are frequently utilized as booster pumps or in other applications where a low net positive suction head (NPSH) is accessible.

Their ability to handle high flow rates and operate effectively in challenging environments makes them suitable for a wide range of applications, including those requiring high-pressure water delivery.

Post time: Aug-22-2024