What Is Single Stage Centrifugal Pump?

A single-stage centrifugal pump features a single impeller that rotates on a shaft inside a pump casing, which is engineered to generate fluid flow when powered by a motor. They are commonly used in various applications due to their simplicity and effectiveness.

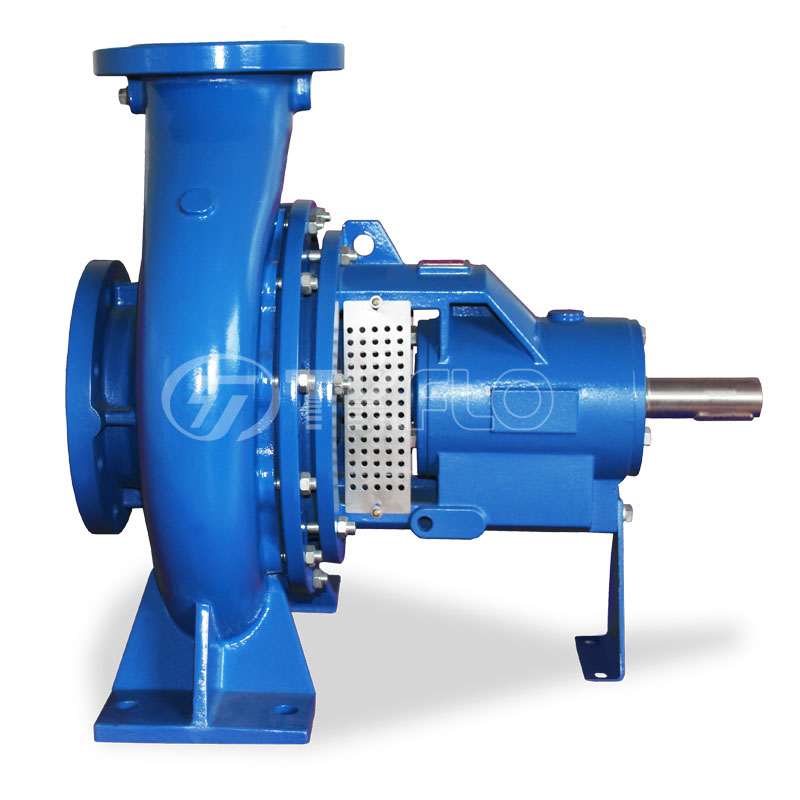

LDP series single-stage end-suction horizontal centrifugal pumps are made by way of improving the design of NT series horizontal centrifugal pumps of ALLWEILER PUMPS company with the performance parameters identical to those of NT series and in line with the requirements of ISO2858.

1.Compact structure. These series pumps have an Horizontal structure, beautiful appearance and less area of occupied land.

2.Stable running, low noise, high concentricity of assembly. The clutch is used to link both pump and motor, making the impeller of a good balance of moving-resting, resulting in no vibration during running and improving the environment of use.

3.No leakage. A mechanical seal antiseptic carbide alloy and packing seal of is used for the shaft sealing.

4.Convenient service. Service can be easily done without removing any pipeline because of the back-door structure.

Single Stage Centrifugal Pump Applications

Single Stage End Suction Centrifugal pumps are commonly used in various applications, including water supply, industrial processes for pressure boosting and liquid transfer, ventilation, air conditioning, heating, and agricultural irrigation.

Multi-stage Pump Definition

A multi-stage pump is a type of pump that contains multiple impellers (or stages) arranged in series within a single casing. Each impeller adds energy to the fluid, allowing the pump to generate higher pressures than a single-stage pump.

GDLF Stainless steel vertical multi-stage high pressure centrifugal pumps mounted with a standard motor, the motor shaft is linked, via the motor seat, directly with the pump shaft with a clutch, both pressure-proof barrel and flow-passing components are fixed in between the motor seat and the water in-out section with pull-bar bolts and both water inlet and outlet of the pump are positioned on one line of the pump bottom; and the pumps can be fitted with an intelligent protector, in case of necessity, to effectively protect them against dry movement, lack-of-phase, overload etc.

Product advantage

1.Compact structure 2.Light weight

3.High Efficiency 4.Good Quality for Long time life

Where are multistage pumps used?

Multistage pumps are utilized for transferring liquids that require high pressure, including applications in water and wastewater treatment, irrigation, industrial processes, and heating and cooling systems.

What Is The Difference Between a Single Stage And a Multi-Stage Pump?

The main difference between single-stage centrifugal pumps and multi-stage centrifugal pumps is their number of impellers, which is referred to as the number of stages in the industrial centrifugal pump industry terminology. As the name suggests, a single-stage pump only has one impeller, while a multi-stage pump has two or more impellers.

A multi-stage centrifugal pump operates by feeding one impeller into the next impeller. As the liquid moves from one impeller to the next, the pressure increases while maintaining the flow rate. The number of impellers required depends on the discharge pressure requirements. The multiple impellers of a multi-stage pump are installed on the same shaft and rotate, essentially similar to individual pumps. A multi-stage centrifugal pump can be considered as the sum of a single stage pump.

Due to the fact that multi-stage pumps rely on multiple impellers to distribute pump pressure and build loads, they can generate greater power and higher pressure with smaller motors, making them more energy-efficient.

Which is the Best Choice?

The choice of which type of water pump is better mainly depends on on-site operating data and actual needs. Choose a single-stage pump or a multi-stage pump based on the height of the head. If single stage and multi-stage pumps can also be used, single stage pumps are preferred. Compared with multi-stage pumps with complex structures, high maintenance costs, and difficult installation, the advantages of a single pump are very obvious. The single pump has a simple structure, small volume, stable operation, and is easy to maintain.

Post time: Nov-25-2024

seth@tkflow.com

seth@tkflow.com