How To Calculate Pump Head?

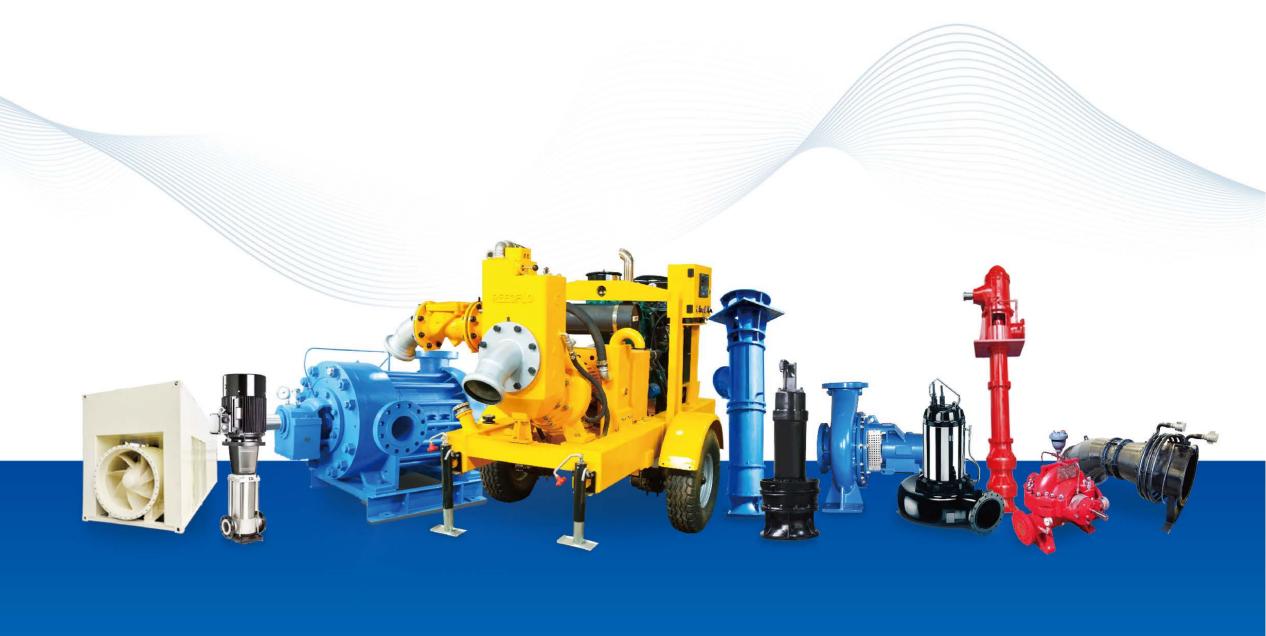

In our important role as hydraulic pump manufacturers, we are aware of the large number of variables that need to be considered when choosing the right pump for the specific application. The purpose of this first article is to begin to shed light on the large number of technical indicators within the hydraulic pump universe, starting with the parameter “pump head”.

What is Pump Head?

Pump head, often referred to as total head or total dynamic head (TDH), represents the total energy imparted to a fluid by a pump. It quantifies the combination of pressure energy and kinetic energy that a pump imparts to the fluid as it moves through the system.In a nutshell, we can also define head as the maximum lifting height that the pump is able to transmit to the pumped fluid. The clearest example is that of a vertical pipe rising directly from the delivery outlet. Fluid will be pumped down the pipe 5 meters from the discharge outlet by a pump with a head of 5 meters. The head of a pump is inversely correlated with the flow rate. The higher the flow rate of the pump, the lower the head. Understanding pump head is essential because it helps engineers assess the pump's performance, select the right pump for a given application, and design efficient fluid transport systems.

Components of Pump Head

To comprehend pump head calculations, it's crucial to break down the components contributing to the total head:

Static Head (Hs): Static head is the vertical distance between the pump's suction and discharge points. It accounts for the potential energy change due to elevation. If the discharge point is higher than the suction point, static head is positive, and if it's lower, static head is negative.

Velocity Head (Hv): Velocity head is the kinetic energy imparted to the fluid as it moves through the pipes. It depends on the fluid's velocity and is calculated using the equation:

Hv=V^2/2g

Where:

- Hv = Velocity head (meters)

- V = Fluid velocity (m/s)

- g = Acceleration due to gravity (9.81 m/s²)

Pressure Head (Hp): Pressure head represents the energy added to the fluid by the pump to overcome pressure losses in the system. It can be calculated using Bernoulli's equation:

Hp=Pd−Ps/ρg

Where:

- Hp = Pressure head (meters)

- Pd = Pressure at the discharge point (Pa)

- Ps = Pressure at the suction point (Pa)

- ρ = Fluid density (kg/m³)

- g = Acceleration due to gravity (9.81 m/s²)

Friction Head (Hf): Friction head accounts for the energy losses due to pipe friction and fittings in the system. It can be calculated using the Darcy-Weisbach equation:

Hf=fLQ^2/D^2g

Where:

- Hf = Friction head (meters)

- f = Darcy friction factor (dimensionless)

- L = Length of pipe (meters)

- Q = Flow rate (m³/s)

- D = Diameter of pipe (meters)

- g = Acceleration due to gravity (9.81 m/s²)

Total Head Equation

The total head (H) of a pump system is the sum of all these components:

H=Hs+Hv+Hp+Hf

Understanding this equation allows engineers to design efficient pump systems by considering factors such as the required flow rate, pipe dimensions, elevation differences, and pressure requirements.

Applications of Pump Head Calculations

Pump Selection: Engineers use pump head calculations to select the appropriate pump for a specific application. By determining the required total head, they can choose a pump that can meet these requirements efficiently.

System Design: Pump head calculations are crucial in designing fluid transport systems. Engineers can size pipes and select appropriate fittings to minimize friction losses and maximize system efficiency.

Energy Efficiency: Understanding pump head helps in optimizing pump operation for energy efficiency. By minimizing unnecessary head, engineers can reduce energy consumption and operating costs.

Maintenance and Troubleshooting: Monitoring pump head over time can help detect changes in system performance, indicating the need for maintenance or troubleshooting issues such as blockages or leaks.

Calculation Example: Determining Total Pump Head

To illustrate the concept of pump head calculations, let's consider a simplified scenario involving a water pump used for irrigation. In this scenario, we want to determine the total pump head required for efficient water distribution from a reservoir to a field.

Given Parameters:

Elevation Difference (ΔH): The vertical distance from the water level in the reservoir to the highest point in the irrigation field is 20 meters.

Frictional Head Loss (hf): The frictional losses due to the pipes, fittings, and other components in the system amount to 5 meters.

Velocity Head (hv): To maintain a steady flow, a certain velocity head of 2 meters is required.

Pressure Head (hp): Additional pressure head, such as to overcome a pressure regulator, is 3 meters.

Calculation:

The total pump head (H) required can be calculated using the following equation:

Total Pump Head (H) = Elevation Difference/Static Head (ΔH)/(hs) + Frictional Head Loss (hf) + Velocity Head (hv) + Pressure Head (hp)

H = 20 meters + 5 meters + 2 meters + 3 meters

H = 30 meters

In this example, the total pump head required for the irrigation system is 30 meters. This means the pump must be able to provide enough energy to lift the water 20 meters vertically, overcome frictional losses, maintain a certain velocity, and provide additional pressure as needed.

Understanding and accurately calculating the total pump head is crucial for selecting an appropriately sized pump to achieve the desired flow rate at the resulting equivalent head.

Where can I find the pump head figure?

The pump head indicator is present and can be found in the data sheets of all our main products. To obtain more information on the technical data of our pumps, please contact the technical and sales team.

Post time: Sep-02-2024

seth@tkflow.com

seth@tkflow.com