Overview Of Product

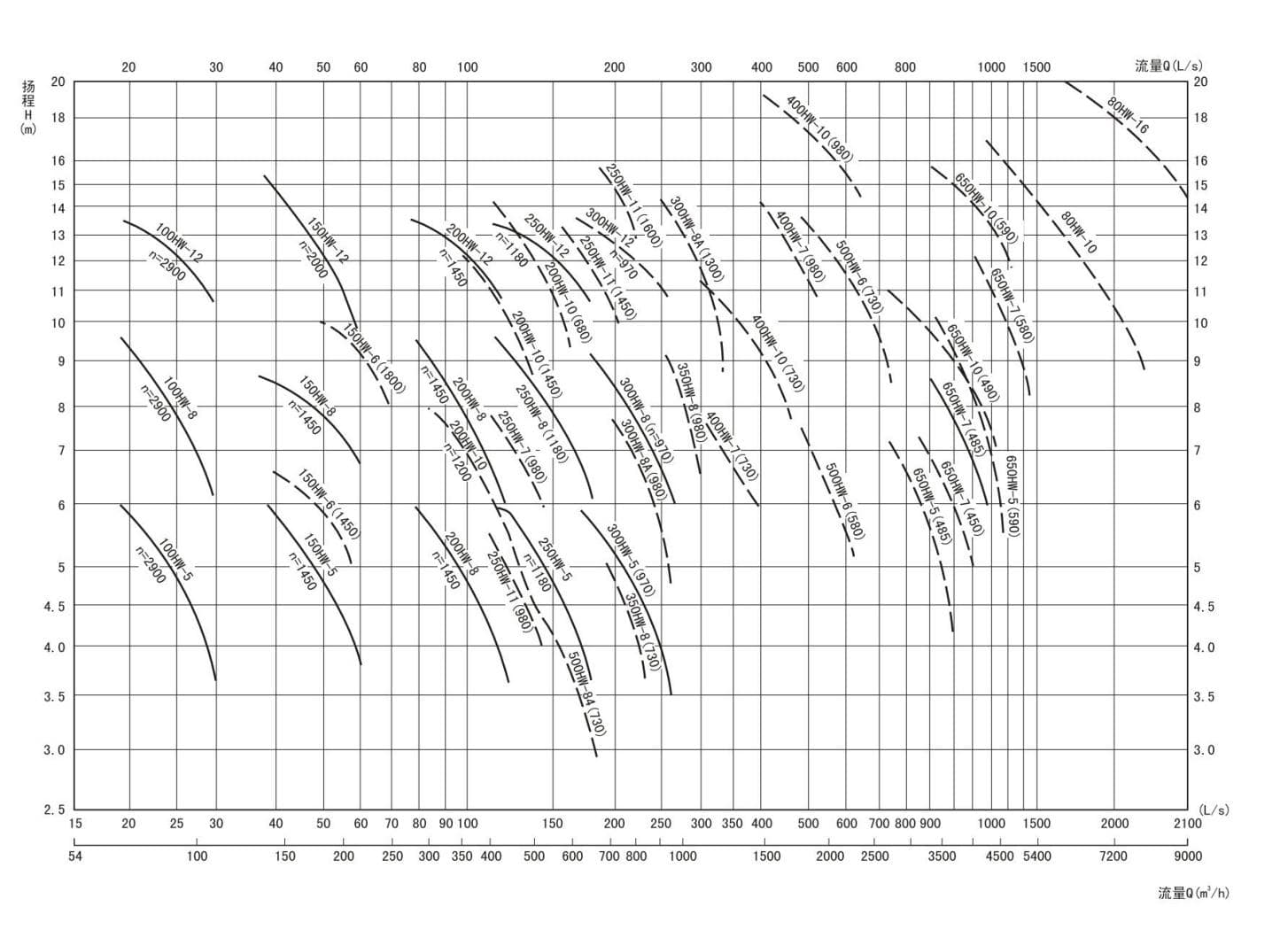

● Performance Range

Flow 130~9000m /h, head :3.5~22m.

● Features

Simple structure, reliable use, easy installation, high efficiency, small body, light weight.

● Mode of Actuation

Direct and variable actuation. The common movers are motor and diesel engine. Please note the model (power, rotating speed) of the mover so as to make sure of the norms of the clutch or the belt pulley.

● Purpose

Model HW pump is a horizontal single stage single suction volute mixed flow pump and suitable for transporting pure water or the other liquid with both physical and chemical natures similar to those of water, with the temperature of the liquid to be transported not over 50 , for the farm land irrigation, industrial and city water supply and drainage and multiple places.

● Water Pump Direction

Viewing from the pump inlet, the impeller rotates counter clockwise generally (clockwise with 650HW-5, -7, -10 pump).

Structure And Function

● Model HW pump mainly consists of pump cover, impeller, pump casing, shaft, muff and bearing body (aperture 350mm) or bearing stand (aperture 400mm) etc. Parts.

● The pump cover is connected to the pump casing and the water-in pipe separately. There should a proper interval between the planes of both pump cover and impeller, too small interval will produce friction; while too big will cause the pressured water inside of the pump to flow back greatly to have the pump efficiency lowered. The practically used proper interval is 0.3~0.7mm (push the pump shaft to the pump inlet) and the interval can be adjusted through increasing or decreasing the paper pad thickness.

● The shaft seal is formed with packing, packing gland, packing ring and the packing box on the pump casing (no packing ring with 150HW and 200HW pumps) and functions to prevent air from being sucked into the pump and too much water from flowing out axially.

● The muff is used to protect the pump shaft and can be replaced after getting worn out.

● The pump shaft is supported with a single-line centripetal ball bearing. The bearing can be lubricated with lubricating oil-with he oil amount controlled in between the marking lines of the oil leveler rod; also with lubricating grease-filled during pump assembly or during use by means of removing both front and rear covers.

● The screw hole on the top of the pump casing is used to prime leading water or link a vacuum pump for exhaust leading water.

● To widen the pump's range of use and meet with the users' different requirements, cut the outer diameter of the impeller or use an impeller of different performance (expressed with letter A etc. Added).

● The accessories of 150~350HW pump include inlet and outlet dead and flexible elbows, foot valve, belt pulley or clutch; and of 400~650HW pump include inlet and outlet dead and flexible elbows, check valve, belt pulley or clutch. Select-able by users.

● See Table 1 and 2 for the bearing model and packing norm of model HW pump.

|

Pump model |

Bearing model |

Packing norm |

|

oil soaked asbestos packing |

||

| 150HW-5,-8,-12 | 6306 | 8×8×135 |

| 150HW-6 | 6307 | 10×10×157 |

| 200HW-5,-8,-10,-12 | 6308 | 10×10×188 |

|

250HW-5,-8,-7,-11,-12 300HW-5,-8,-8A,-12 350HW-8 |

6311 | 13×13×228 |

|

Pump model |

Bearing model |

Packing norm |

|

oil soaked asbestos packing |

||

| 400HW-7,-8,-10 |

6312(7312AC & 7312AC/DT)★ |

13×13×261 |

| 500HW-11 |

6314 |

15×15×299 |

| 650HW-5,-7,-10 |

6322(7322AC & 7322AC/DT)★ |

19×19×437 |

| 800HW-10,-16 |

27324 & 6324 |

19×19×437 |

Hw Series Pump Flow-Head Curve Chat

For More details

Please send mail or call us.

TKFLO sales engineer offer one-to-one

business and technical services.

seth@tkflow.com

seth@tkflow.com