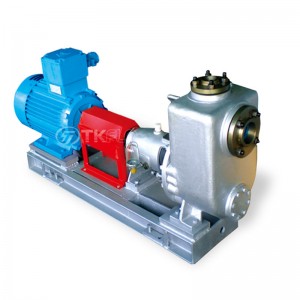

Model SLO and SLOW pumps are single-stage double-suction split volute casing centrifugal pumps and used for liquid transportation for water works, air-conditioning circulation, building, irrigation, drainage pump station, electric power station, industrial water supply system, fire-fighting system, shipbuilding and so on.

ASN pump Advantage

1.Compact structure nice appearance, good stability and easy installation.

2.Stable running the optimally designed double-suction impeller makes the axial force reduced to the minimum and has a blade-style of very excellent hydraulic performance, both internal surface of the pump casing and the impeller's surface, being precisely cast, are extremely smooth and have a notable performance vapor corrosion resisting and a high efficiency.

3. The pump case is double volute structured, which greatly reduces radial force, lightens bearing's load and long bearing's service life.

4.Bearing use SKF and NSK bearings to guarantee a stable running, low noise and long duration.

5.Shaft seal use BURGMANN mechanical or stuffing seal to ensure a 8000h non-leak running.

6 . Flange standard: GB, HG, DIN, ANSI standard, according to your requirements

Technical data

| Diameter | DN 80-800 mm |

| Capacity | no more than 11600m3/h |

| Head | no more than 200m |

| Liquid Temperature | up to105 ºC |

List of Main Parts Material

| Part name | Material | GB standard |

| Pump casing | Cast iron Ductile iron Cast steel Stainless steel |

HT 250 QT400-18 ZG230-450 & as clients request |

| Impeller | Bronze Cast iron Bronze/brass Stainless steel |

ZCuSn10Pb1 Ht 250 ZCuZn16Si4 & as clients request |

| Shaft | Carbon steel Stainless steel |

2Cr13 40Cr |

| seal-ring on pump casing | Bronze Cast iron Brass Stainless steel |

ZCuSn10Pb1 HT 250 ZCuZn16Si4 & as clients request |

Applicant

Municipal, construction, ports

Chemical industry, paper making, paper pulp industry

Mining and metallurgy

Fire control

Environmental protection

seth@tkflow.com

seth@tkflow.com