Product Description

GDL non-self suction vertical multi-stage centrifugal pumps mounted with a standard motor, the motor shaft is linked, via the motor seat, directly with the pump shaft with a clutch, both pressure-proof barrel and flow-passing components are fixed in between the motor seat and the water in-out section with pull-bar bolts and both water inlet and outlet of the pump are positioned on one line of the pump bottom; and the pumps can be fitted with an intelligent protector, in case of necessity, to effectively protect them against dry movement, lack-of-phase, overload etc.

Product advantage

Compact structure

Light weight

High Efficiency

Good Quality for Long time life

Running Condition

Thin, clean, non-combustible non-explosive liquids containing no solid grains or fibers.

Liquid temperature: constant-temperature type -15~+70℃,hot-water type +70~120℃.

Ambient temperature: max. +40℃.

Elevation: max. 1000m

Note: please note it at the model selection in case the elevation is over 1000m.

TECHNICAL DATA

Data range

| Capacity | 0.8-150 m3/h |

| Head | 6-400 m |

| Liquid Temperature | -20-120 ºC |

| Operation pressure | ≤ 40bar |

Attention: More detailed technical data for Vertical Multistage Centrifugal High Pressure Water Pump please contact Tongke.

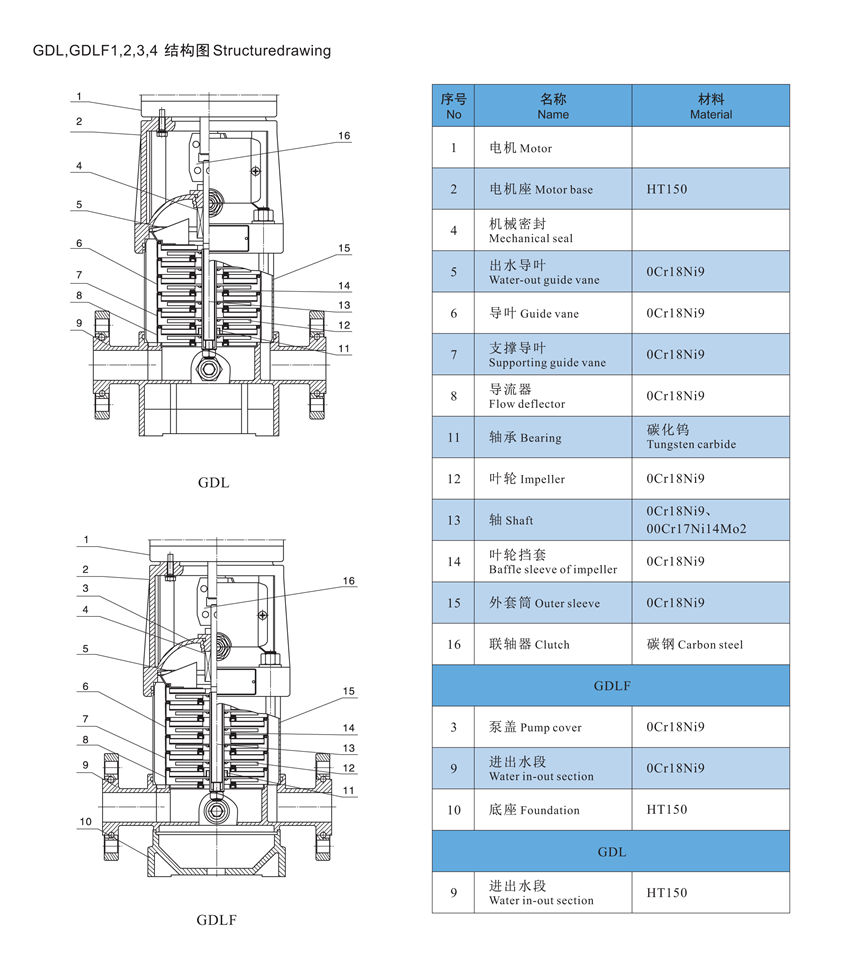

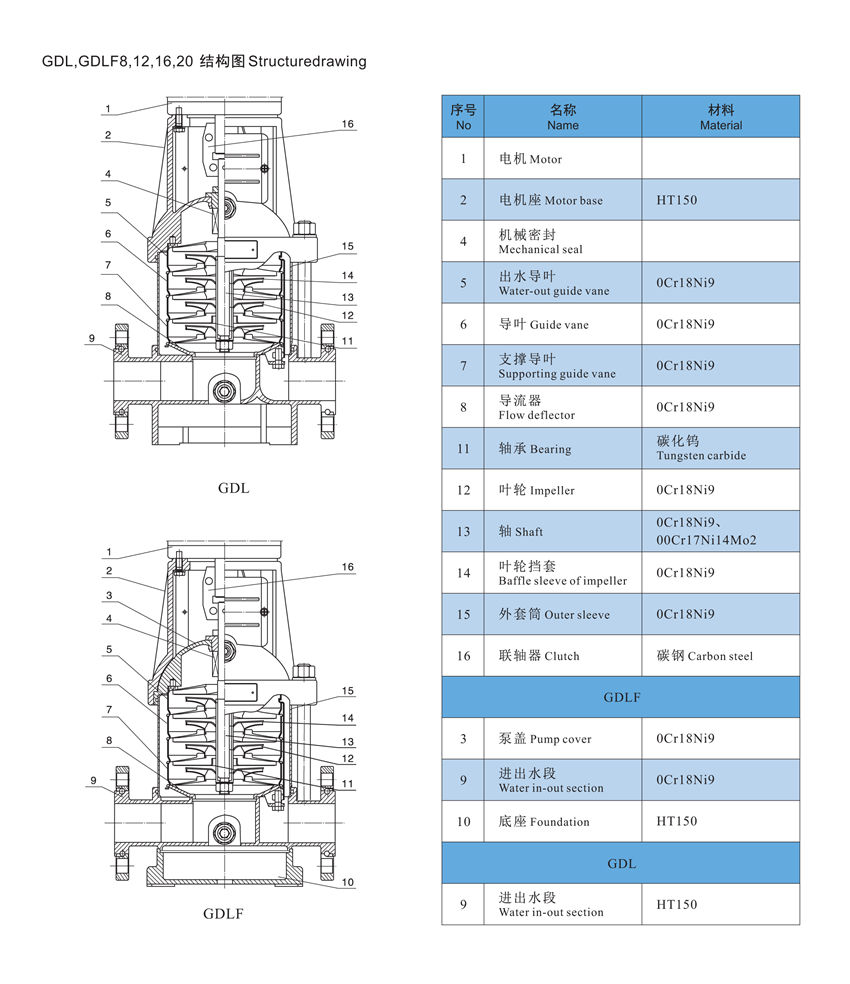

Main parts List

| Part | Material |

| Shaft seal form | Packing gland or Mechanical seal |

| Impeller | Cast iron, Ductile iron, Carbon steel , Stainless steel, Bronze, Duplex SS |

| Bearing | Qualified China Bearing or NTN/NSK/SKF |

| Shaft | 2Cr13, 3Cr13, Duplex SS |

Attention: Particular material for project please contact Tongke engineer for suggestions.

APPLICANT

Pump Applicant

GDL are the products of multiple functions, applicable for transporting various different media from tap water to industrial liquids and suitable for different ranges of temperature , flow and pressure .

GDL is applicable for non-corrosive liquids while GDLF for lightly corrosive ones.

Water supply: filter and transportation and quartering water feed for water works, boost for main pipes and high buildings.

Industrial boost: flowing water system, cleaning system, high pressure rinsing system, fire fighting system.

Industrial liquid transportation: cooling & air-conditioning system, boiler water supply & condensing system, completion of machine tools, acid and alkali.

Water treatment: extra-filter system, reverse osmosis system, distilling system, separator, swimming pool.

Irrigation: farmland irrigation, sprinkler irrigation, trickle irrigation.

Part of Sample Project

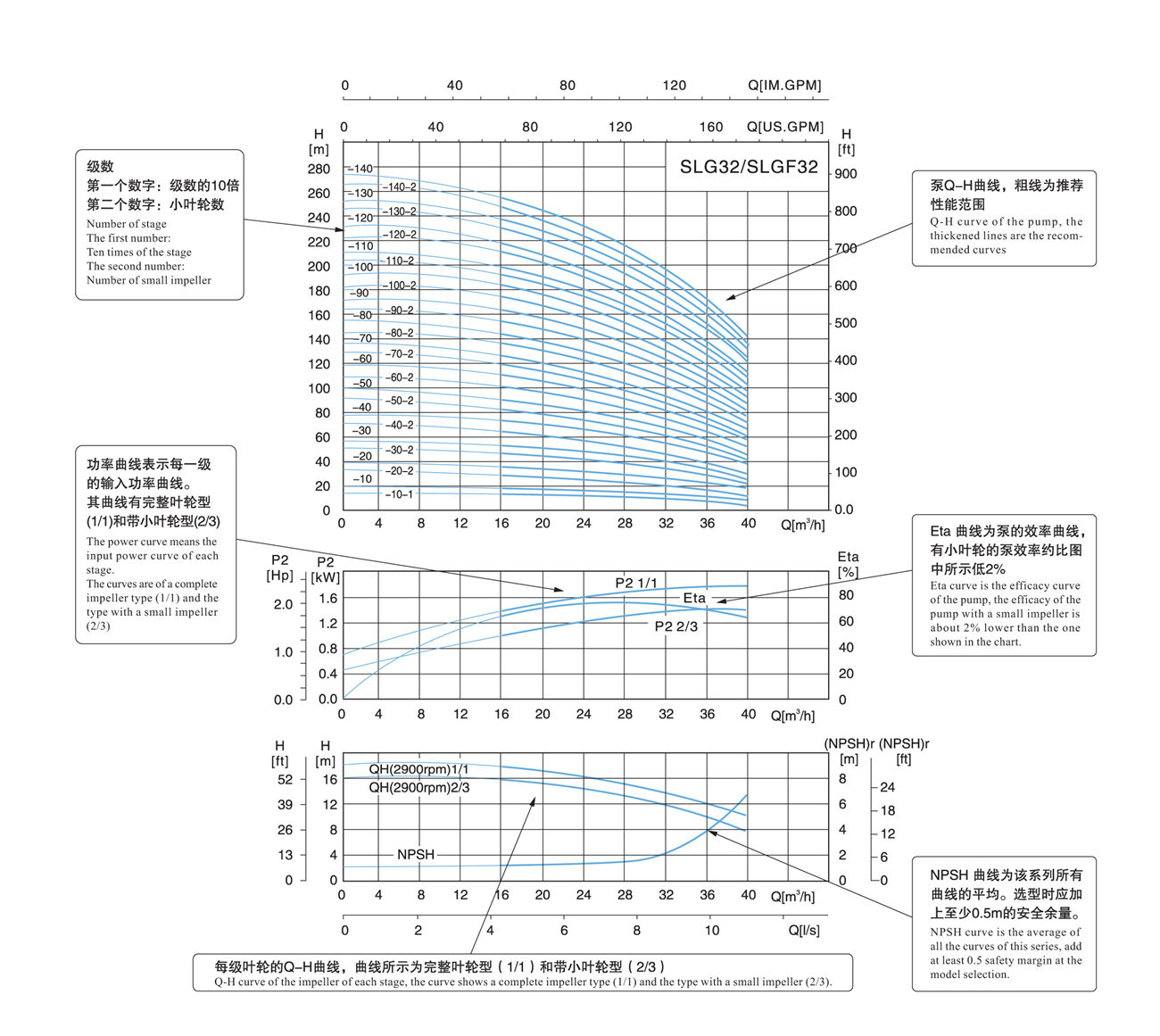

CURVE

The description below is applicable for the curves shown on the back:

1. All the curves are based on the values measured at the constant speed of 2900rpm or 2950rpm of the motor.

2. The allowed curve differences comply with ISO9906, Appendix A.

3. The water at 20 containing no air is used for the measurement, the moving viscosity of it is 1mm /s.

4. The pump shall be used within the performance range shown by the thickened curves so as to prevent against overheat due to an undersized flow and prevent the motor against overload due to an oversized flow.

Pump performance chart explanation

seth@tkflow.com

seth@tkflow.com