Fluid Machinery Energy-saving Integrated Solution

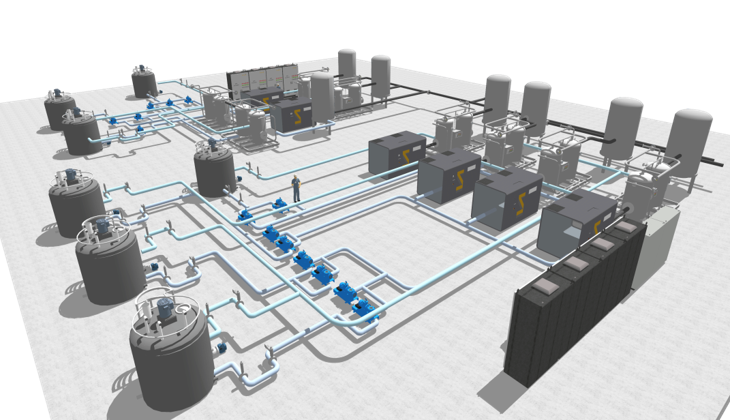

Our company is dedicated to becoming a provider of efficient and intelligent fluid machinery systems. We achieve intelligent control of the complete system through the use of high-efficiency centrifugal pumps, variable frequency speed control, direct drive, and an informatization management platform. By selecting different equipment according to actual working conditions for optimal system integration, we ensure that the complete set of equipment operates under optimal conditions, achieving energy savings of 20%-50%.

Core Technology

Brushless Doubly Fed Frequency Conversion Integrated Motor

The brushless doubly fed motor adopts the structure of an asynchronous motor while offering the performance characteristics of a synchronous motor. Its stator features both power windings and control windings, utilizing supersynchronous frequency conversion speed control, requiring only half of the motor’s rated power for the control winding.

The control winding not only undertakes the motor’s speed regulation and characteristic control but also shares the output power with the power winding.

Core Technology

High-Efficiency Energy-Saving Pump

Efficient Ternary Flow Impeller

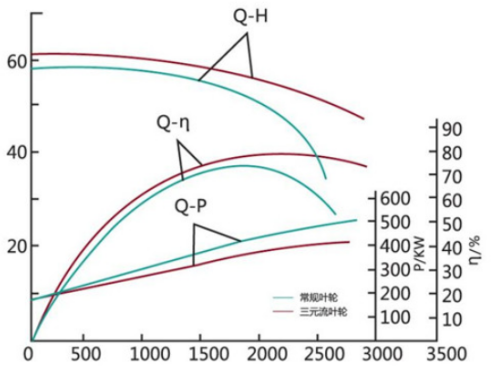

Performance curve comparison chart for different impellers of pumps with the same parameters

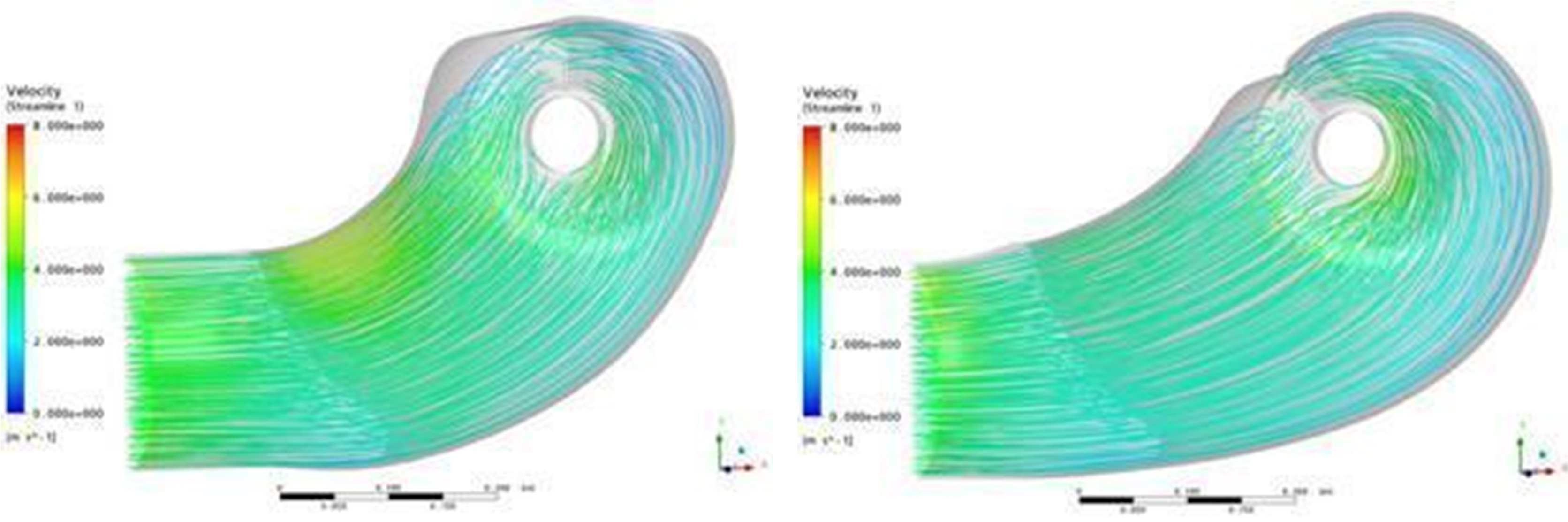

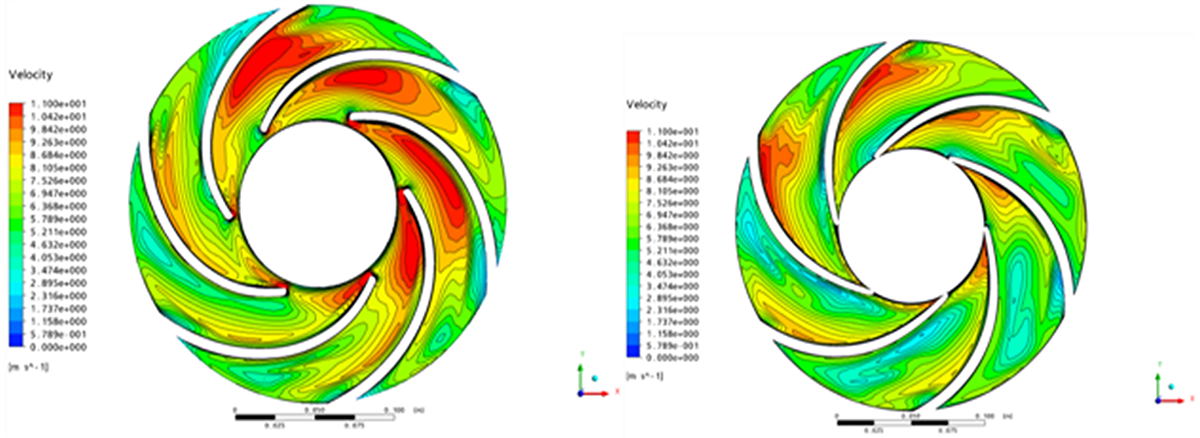

Utilizing fluid dynamics software, simulations are conducted on the impeller, suction chamber, and pressure chamber to perform three-dimensional flow field numerical simulations. This optimizes the flow state and energy distribution within the channels.

The pumps designed through simulations incorporate "high-efficiency energy-saving ternary flow impellers," "flow field diagnostic technology," and "3D printing precision casting technology" among other advanced technologies.

The efficiency of these pumps can increase by 5% to 40% compared to traditional hydraulic models.

seth@tkflow.com

seth@tkflow.com