Overview of product

ESC series Closed Coupled Mono-block Single Stage End Suction Centrifugal pump

Installation forms are as follows:

- Standard option: Pump assembly with base-plate.

- For the foundation with an extremely good flatness: Pump assembly with iron cushion.

- For the application in unit: Pump assembly only, without base-plate or iron cushion.

- A compact structure due to integrated design and rigid coupling.

- Motor with thrust bearing can effectively compensate the axial force influence caused by impeller.

- Variety of optional materials on different application.

Working condition

1.Pump inlet pressure is less than 0.4MPa

2.Pump system that is to say the pressure at the suction the stroke 1.6MPa, please notify the pressure for the

system at work when ordering.

3.Proper medium: the medium for pure-water pumps should have no corrosive liquid and the volume of non-melting medium solid should not be over 0.1% of the unit volume and the graininess less than 0.2mm. Please notify at order if the medium to be used with small grain.

4.No larger than 40 of the ambient temperature, no higher than 1000m of the above-sea level and no more

than 95% of the relative humid

Application

• Pumping clean or slightly contaminated water (max.20 ppm) containing no solid particles for circulation, conveying and pressurized water supply.

• Cooling/cold water, sea water and industrial water.

• Applying on municipal water supply, irrigation, building, general industry, power stations, etc.

• Pump assembly composed of pump head, motor and base-plate.

• Pump assembly composed of pump head, motor and iron cushion.

• Pump assembly composed of pump head and motor

• Mechanical seal or packing seal

• Installation and operation instructions

Technical parameters

| Capacity | 5-2000m3/h |

| Head | 3-150meter |

| Rotating speed | 2950/1480/980rpm |

| Liquid Temperature range | -10~85℃ |

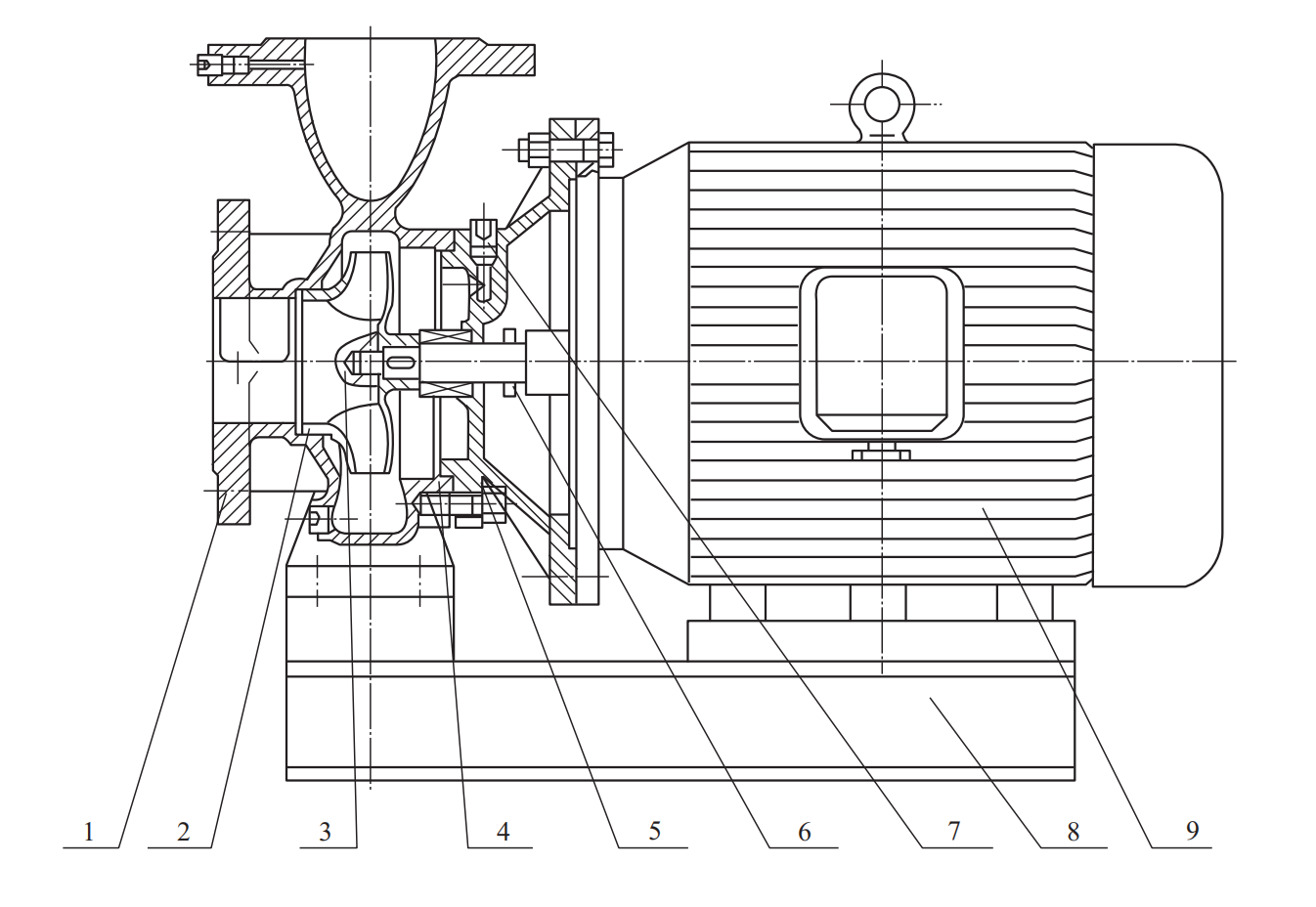

Structure Diagram

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

| Pump casing | Impeller | Impeller nut | Mechanical seal | Pump cover | Water-blocking ring | Plug | Foundation | Motor |

See the figure for the structure. This pump consists of pump, motor and foundation three parts and its structure is formed by pump casing, impeller, pump cover, mechanical seal etc. Components.It is a single-stage single-suction horizontal centrifugal pump and both pump casing and cover are separated from the back side of the impeller, that is the back-door structural form. For most of the pumps, a seal ring is set in both front and back of the impeller to make a balance action on the axial force of the rotor.

Both pump and motor are coaxial and a dual-angle contact ball bearing structure used on the projected end of the motor's shaft can partially balance the residual axial force of the pump.With the straight joint between pump and motor, it is not necessary to calibrate when being mounted.

Both of them have a common foundation and a buffer dash pot of model JSD is used to isolate vibration. The outlet of the pump is mounted vertically upward. Contact with technical center if need leftward or rightward.

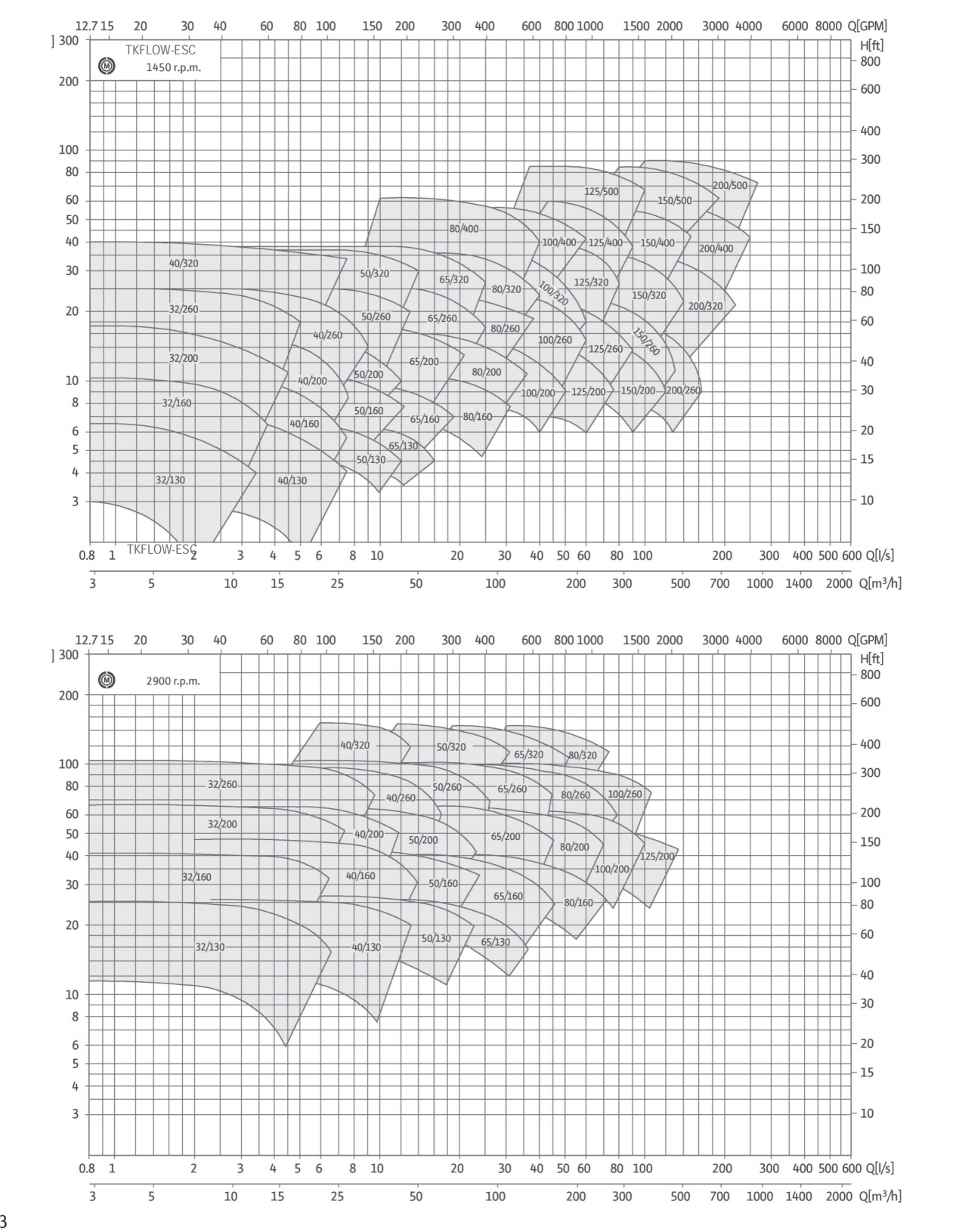

Data range

Pump advantage

1. Compact structure: This series of pumps is horizontal structure, integrated with machine and pump, with beautiful appearance and less floor space, which is 30% less than that of ordinary horizontal pumps;

2. Stable operation, low noise and high concentrically of components: the motor and the pump are directly connected, which simplifies the intermediate structure and enhances the stability of operation. The impeller has good static and dynamic balance, and the vibration is small during operation, which improves the use environment;

3. No leakage: the shaft seal adopts corrosion-resistant cemented carbide mechanical seal, which solves the serious leakage problem of centrifugal pump packing and ensures the clean and tidy operation site;

4. Convenient maintenance: This series of horizontal pumps has a back door structure, so it can be repaired without disassembling the pipeline.

seth@tkflow.com

seth@tkflow.com