TKFLO Electrical Hydraulic motor drive submersible sewage slurry water pump

● Excellent design for big capacity

● High efficiency and energy saving

● High reliability and long duty life cycle.

● Professional forehead pump manufacturing factory

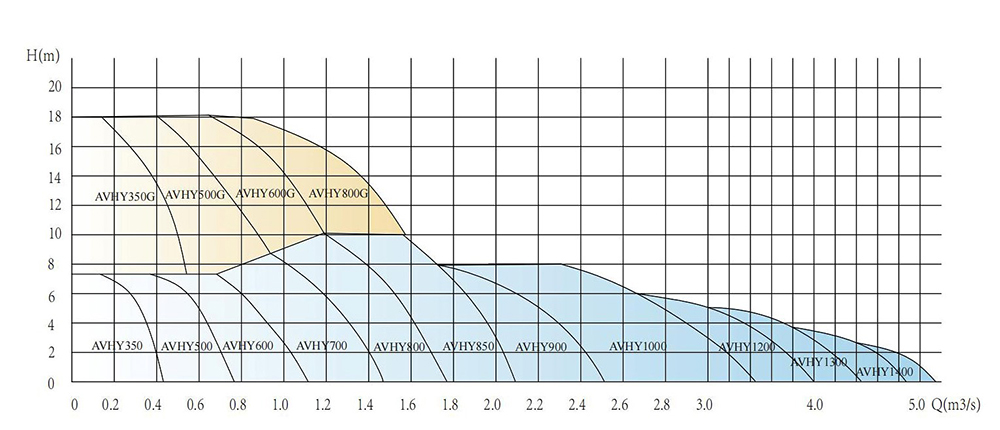

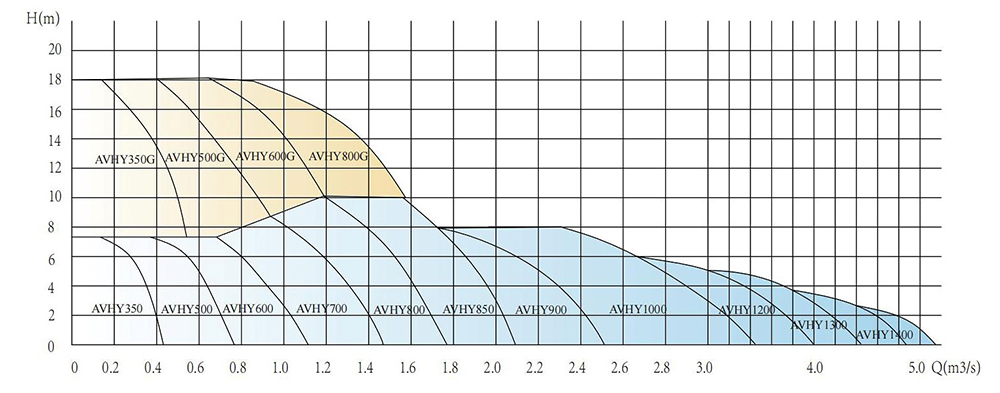

Pump performance range

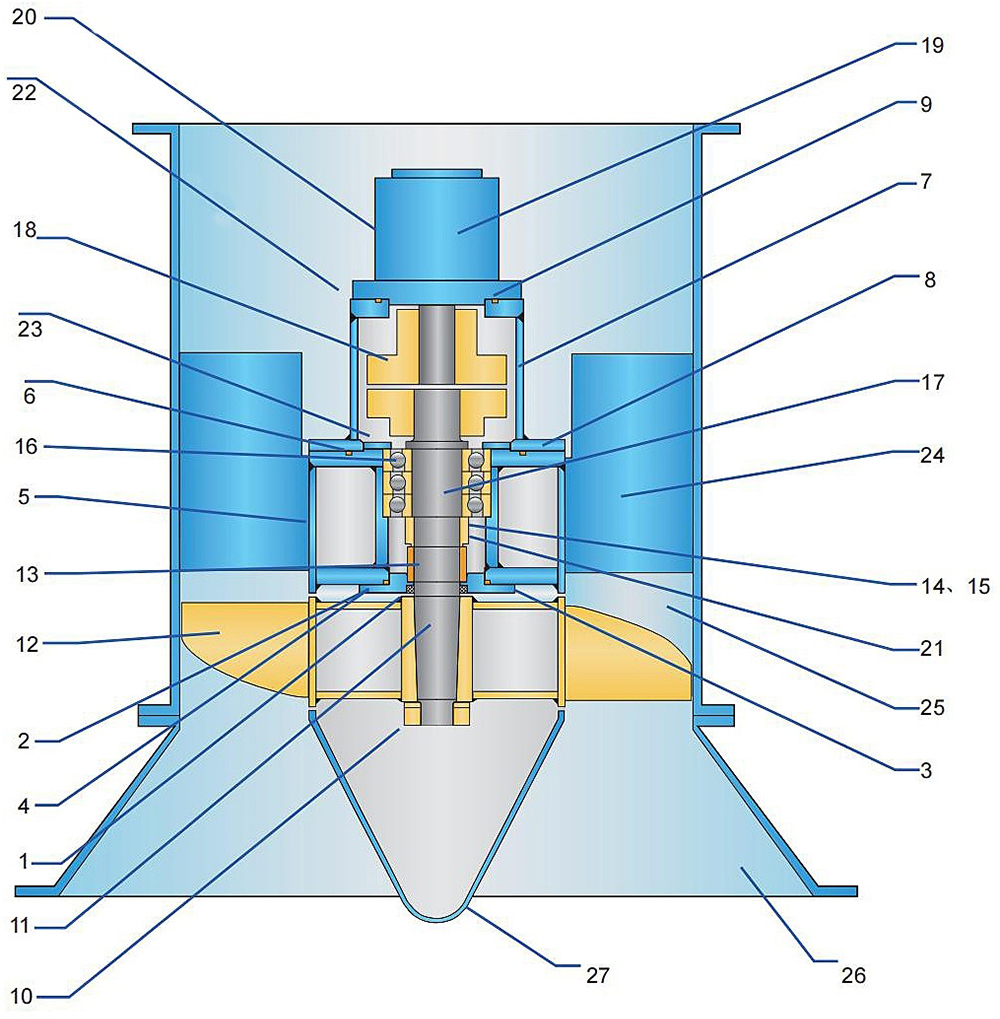

Structure Drawing

TKFLO Hydraulic motor drive submersible pump that uses the power of hydraulics to drive the impeller via flexible hoses. This replaces a fixed motor, a long, rigid shaft and the supporting structure common to most pumps that can move very large quantities of water.

|

NO. |

Name |

NO. |

Name |

|

1 |

Lip Seal (Synthetic Rubber & Stainless steel Garter Spring) |

16 |

Bearing |

|

2 |

Bolts: Fasten End P1-Bearing Box (Grade 5) |

17 |

Hydrauflo Shaft (304 Stainless Steel) |

|

3 |

End Plate (ASTM A588, Carbon steel) |

18 |

Shaft Coupling Assembly (Steel) |

|

4 |

O-ring: End plate/ Bearing Box |

19 |

Hydraulic Motor (Steel Casting) |

|

5 |

Bearing Box (ASTM A588, Carbon Steel) |

20 |

Mounting Flanges/ Adapters |

|

6 |

O-Ring: Bearing Box/Motor Mount |

21 |

Bronze Spacer (Bronze 660) |

|

7 |

Motor Mount(ASTM A242 Carbon Steel) |

22 |

Bolts-Hydraulic Motor To Mount (Grade 5) |

|

8 |

8Bolts: Motor Mount-Bear g Box(Grade 5) |

23 |

Bearing Retainer (ASTM A242,Carbon Steel) |

|

9 |

O-Ring: Motor Mount/Hydraulic Motor |

24 |

Distributor Blades (ASTM A242 Carbon Steel) |

|

10 |

Propeller Nut (AISI 1026 Steel) |

25 |

Wear Ring/Liner (304 Stainless Steel) |

|

11 |

Propeller Key (AISI 1018 Steel) |

26 |

Guide Blades |

|

12 |

Propeller (S/S Blades,A588 Carbon Steel) |

27 |

Guide Hub |

|

13 |

Mechanical Seal Assembly (Ceramic & Stainless Steel Spring) |

|

|

|

14 |

14 Bearing Lock-Nut (ANSI C1015 Steel) |

|

|

|

15 |

Bearing Lock-Washer (ANSI C1015 Steel) |

|

|

|

Due to our continual improvement of our products, we reserve the right to change designs and specifications. |

|||

TECHNICAL DATA

High Volume Medium-Head

● Capacity: 15-18000 m3/h

● Head: 2 – 18m

AVHY type Hydraulic motor drive submersible pump unique design allows the pump to be set up in hours - not months - usually eliminates most of the civil works necessary for installation - saving a lot of money and time, allows the pump to be portable and provides variable speed control.

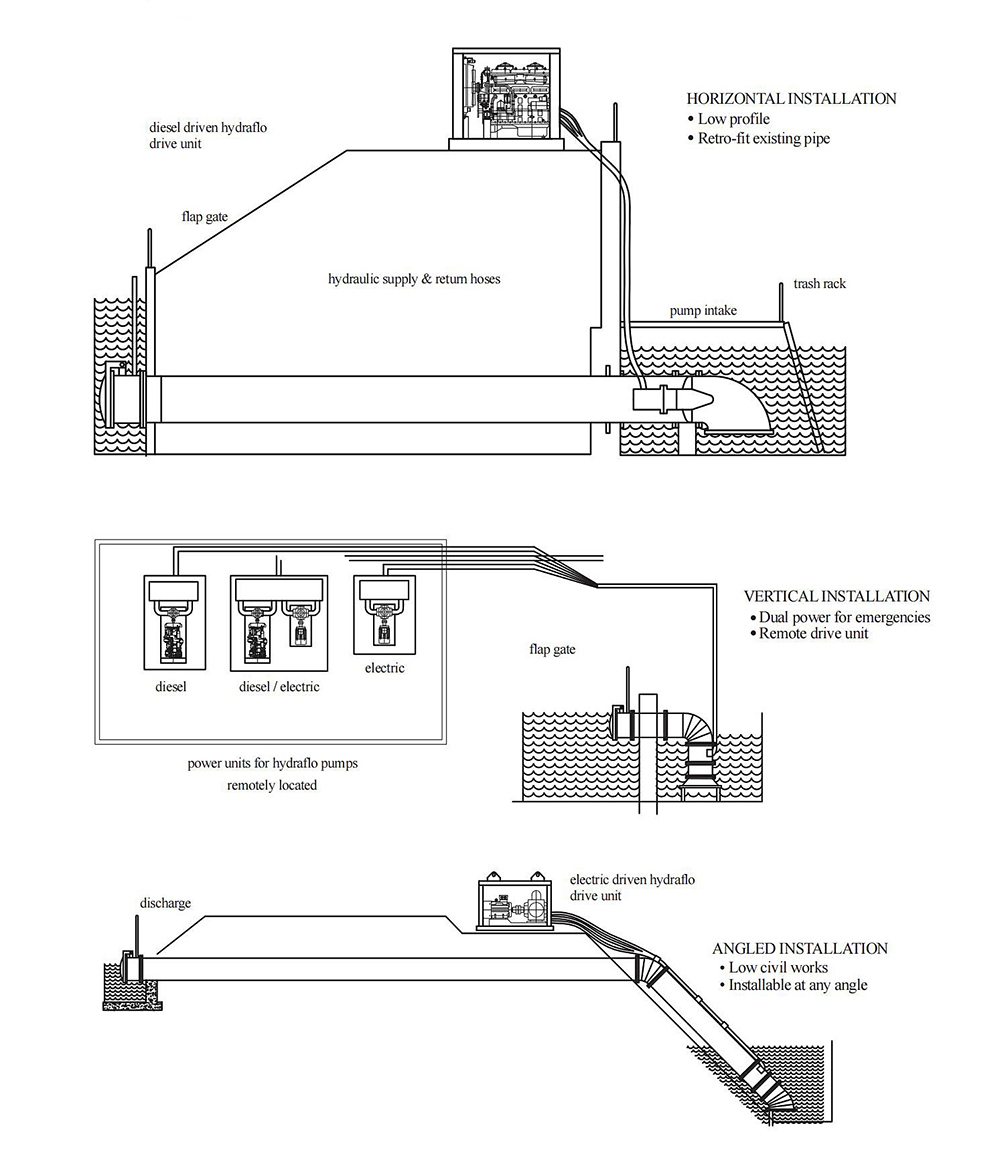

The unique design for multiple installation modes

● Horizontal Installation

● Vertical Installation

● Angled Installation

SKETCH MAP

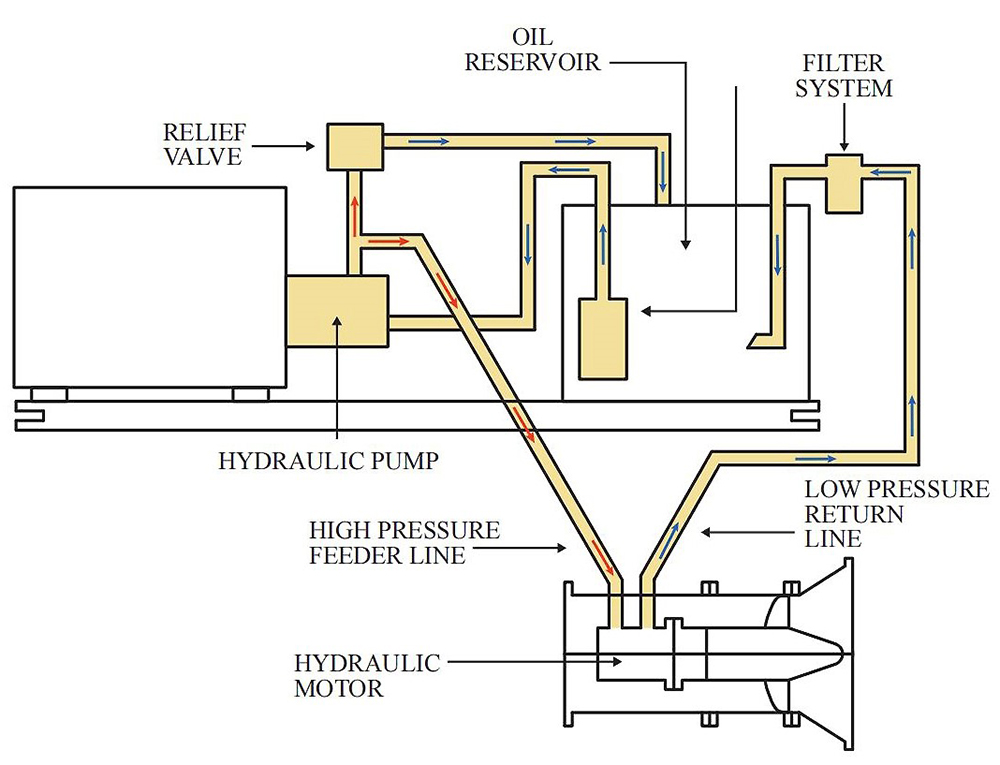

Schematic A shows how the hydraulic system works.

Note that the prime mover can be adepts engine, electric motor or a combination of both. It drives a hydraulic pump which in turn supplies oil to the hydraulic motor in the water pump which is directly connected to the propeller.The hydraulic oil is then

returned to the oil reservoir through the return filter.Then,the hydraulic oil returns through a strainer and back to the hydraulic pump,completing the circuit.

A relief valve from the high pressure side to the oil reservoir,serves to by-pass the power transmission fluid and divert flow in the event that an object gets lodged in the propeller. This is a very important safety feature available only with hydraulic systems which protects all components from shock loads.

Where variable flows are needed (such as in sewage effluent or "piped in"Storm water pumping), the propeller speeds can be infinitely adjusted automatically through the hydraulic power transmission system to match up with any combination of water flows and head conditions.

FAQ

Q1. Are you a manufacturer?

Yes, we have been in pumps manufacturing and oversea marketing industry over 15 years.

Q2. What markets do your pumps export to?

More than 20 countries and areas, such as South-East Asia, Europe, North & South America, Africa, Oceanic, Middle East countries...

Q3. What information should I let you know if I want to get a quotation?

Please let us know the pump capacity, head, medium, operation situation, quantity, etc. As much as your provide, the precision and accurate model selection.

Q4. Is it available to print our own brand on the pump?

Totally acceptable as international rules.

Q5. How can I get the price of your pump?

You can connect with us through any of the following contact information. Our personalized service person will respond you within 24 hours.

APPLICANT

Pump Applicant

Applications vary from small, basic electric motor driven to diesel engine driven, packaged systems.

Standard units are designed to handle fresh water, but special materials are available for sea water and special liquid applications.

The TONGKE Fire Pumps give superior performance in Agriculture, General Industry, Building Trade, Power Industry, Fire Protection, Municipal, and Process applications.

TONGKE Pump extensive distribution system provides worldwide technical and commercial support with qualified personnel in most major Asia and international .

seth@tkflow.com

seth@tkflow.com