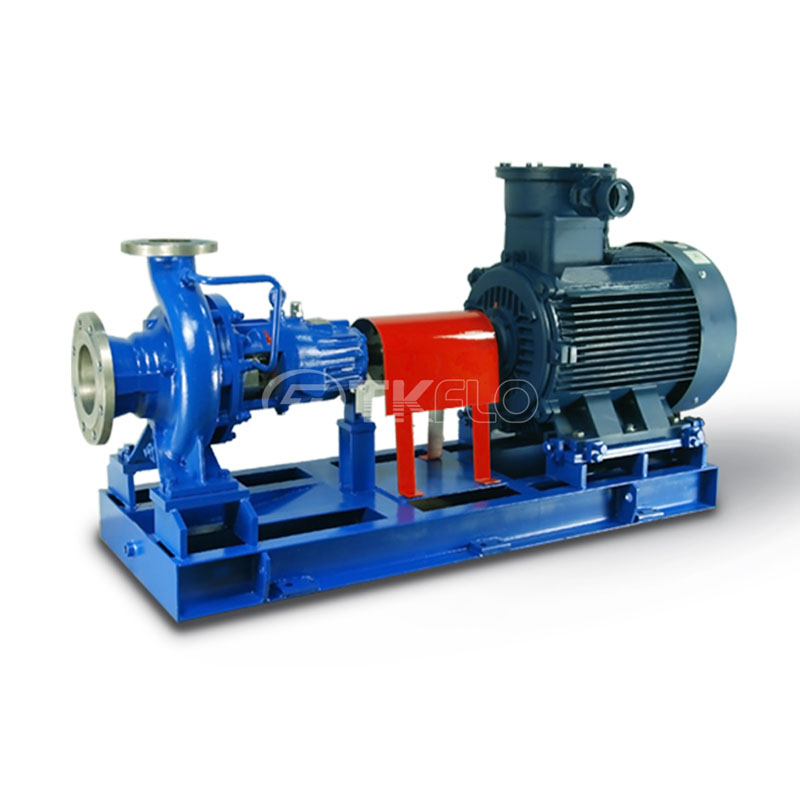

Product Description

CZ series standard chemical pumps are horizontal, single stage, end suction type centrifugal pumps, in accordance with standards of DIN24256, ISO2858, GB5662, they are basic products of standard chemical pump, transferring liquids like low or high temperature, neutral or corrosive, clean or with solid, toxic and inflammable etc.

Product advantage

CASING √

Foot support structure

IMPELLER √

Close impeller. Thrust force of CZ series pumps are balanced by back vanes or balance holes, rest by bearings.

COVER √

Along with seal gland to make sealing housing, standard housing should be equipped with various kinds of seal types.

SHAFT SEAL √

According to different purpose, seal can be mechanical seal and packing seal. Flush can be inner-flush, self-flush, flush from outside etc, to ensure good work condition and improve life time.

SHAFT √

With shaft sleeve, prevent shaft from corrosion by liquid, to improve life time. Back pull-out design Back pull-out design and extended coupler, without taking apart discharge pipes even motor, the whole rotor can be pulled out, including impeller, bearings and shaft seals, easy maintenance.

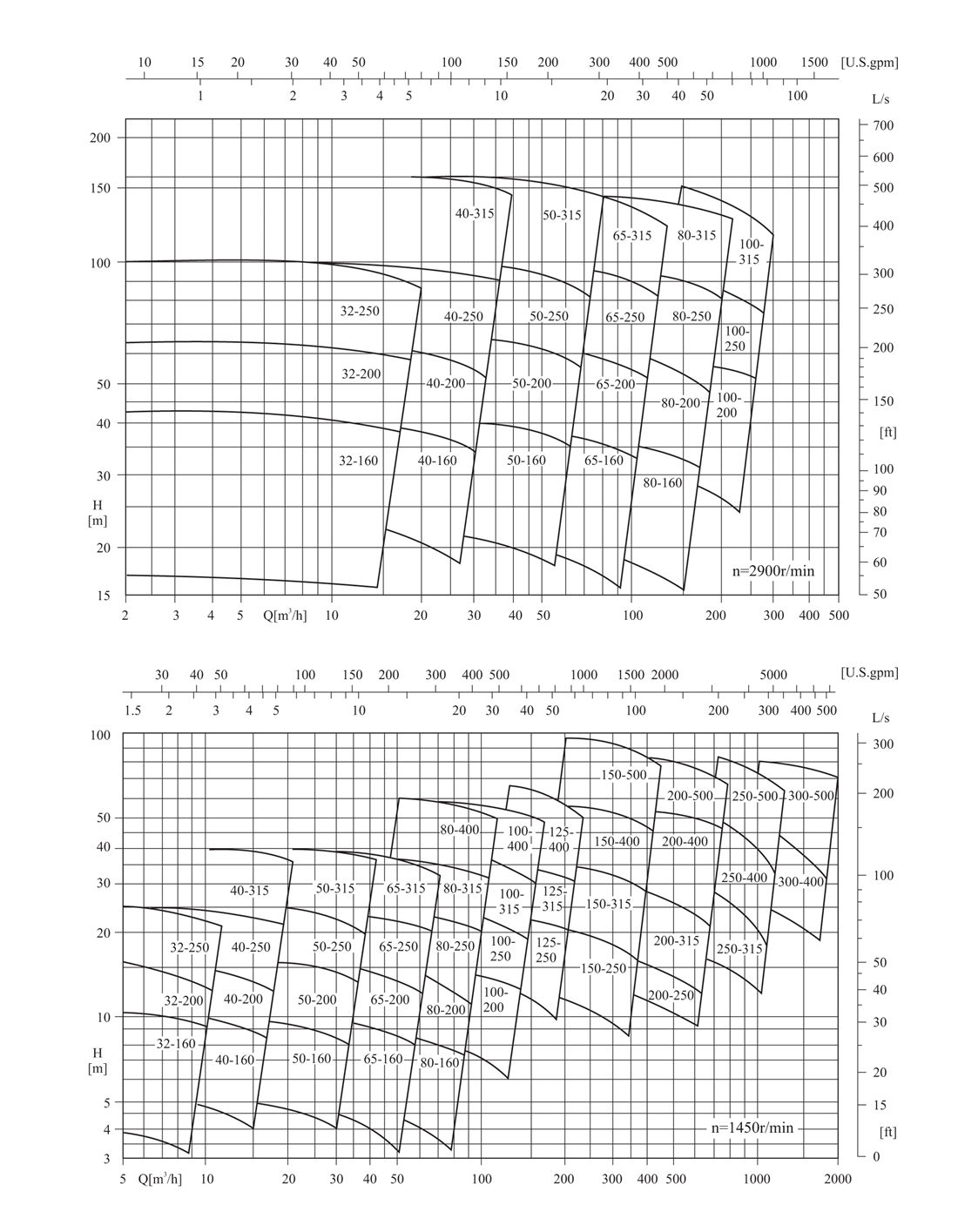

Running Data

Diameter: 32~300 mm

Capacity: ~2000 m /h

Head: ~160 m

Working pressure: ~2 .5 MPa

Working temperature: -80 ~+150℃

TECHNICAL DATA

Data range

Diameter: 32~300 mm

Capacity: ~2000 m /h

Head: ~160 m

Working pressure: ~2 .5 MPa

Working temperature: -80 ~+150℃

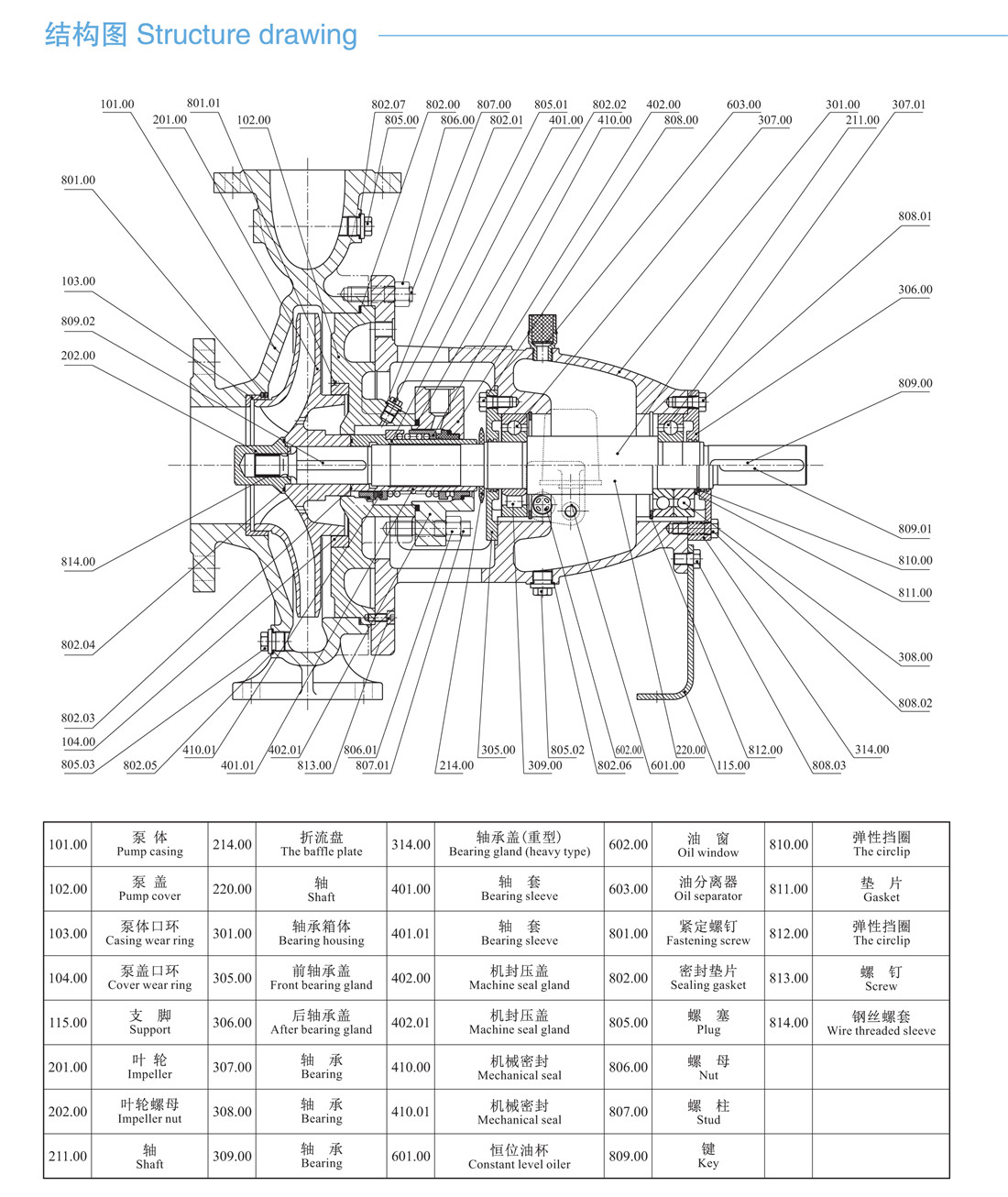

Structure drawing

Characteristics of structure

CASING : Foot support structure

IMPELLER: Close impeller. Thrust force of CZ series pumps are balanced by back vanes or balance holes, rest by bearings.

COVER : Along with seal gland to make sealing housing, standard housing should be equipped with various kinds of seal types.

SHAFT SEAL :According to different purpose, seal can be mechanical seal and packing seal. Flush can be inner-flush, self-flush, flush from outside etc, to ensure good work condition and improve life time.

SHAFT:With shaft sleeve, prevent shaft from corrosion by liquid, to improve life time. Back pull-out design Back pull-out design and extended coupler, without taking apart discharge pipes even motor, the whole rotor can be pulled out, including impeller, bearings and shaft seals, easy maintenance.

APPLICANT

Pump Applicant

Mainly for chemical or petrol chemical area

Refinery or steel plant

Power plant

Making of paper, pulp, pharmacy, food, sugar etc.

Refinery

Petrochemical industry

Coal processing industry and low temperature projects

For transferring:

Inorganic acid and organic acid in different temperature and content, like sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid etc.

Alkaline solutions like sodium hydroxide solutions and sodium carbonate solutions etc in different temperature and content.

Various kinds of salt solution.

Different liquid petro-chemical products, organic compounds, and other corrosive materials and products.

At present, corrosion-proof materials can meet all above requirements. Once acquirement, users should give detailed information of transferred liquid.

Part of Sample Project

seth@tkflow.com

seth@tkflow.com