Product Description

CZ series standard chemical pumps are horizontal, single stage, end suction type centrifugal pumps, in accordance with standards of DIN24256, ISO2858, GB5662, they are basic products of standard chemical pump, transferring liquids like low or high temperature, neutral or corrosive sea water, clean or with solid, toxic and inflammable etc.

Product advantage

CASING √

Foot support structure

IMPELLER √

Close impeller. Thrust force of CZ series pumps are balanced by back vanes or balance holes, rest by bearings.

COVER √

Along with seal gland to make sealing housing, standard housing should be equipped with various kinds of seal types.

SHAFT SEAL √

According to different purpose, seal can be mechanical seal and packing seal. Flush can be inner-flush, self-flush, flush from outside etc, to ensure good work condition and improve life time.

SHAFT √

With shaft sleeve, prevent shaft from corrosion by liquid, to improve life time. Back pull-out design Back pull-out design and extended coupler, without taking apart discharge pipes even motor, the whole rotor can be pulled out, including impeller, bearings and shaft seals, easy maintenance.

TKFLO supply reliable service for Installation and debugging , Spare parts, Maintenance and repair and the equipment upgrades and improvement Installation and commissioning of systems

Installation and commissioning instructions for the pumps.

Our company is responsible for guidance to install and commissioning

Expert help on site, if customers request. Experienced service enginner from TKFLO Service professionally and reliably install pumps.

Travel expenses and labor costs, please confirm with TKFLO.

Helping users to examining attendants.

Inspection of the supplied pumps, valves, etc.

Verification of system requirements and conditions

Supervising all installation steps

Leak tests

Correct alignment of the pump sets

Inspection of measuring instruments fitted for pump protection

Supervising the commissioning, test runs and trial operations including records of operating data

Helping users to train.

TKFLO offers you and your employees an extensive training programmer on the functioning, selection, operation and servicing of pumps and valves. On the proper and safe operation of pumps and valves, including service issues.

Spare parts

Excellent spare parts availability minimizes unplanned downtime and safeguards the high performance of your machine.

We will provide a two-year list of spare parts according to your product type for your reference.

We can quickly provide you with the spare parts you need in the process of use in case of loss caused by the long downtime.

Maintenance and repair

Regular servicing and professional maintenance strategies help to significantly extend a system’s life cycle.

TKLO will repair pumps, motors of any make and – if requested – modernise them to the latest technological standards. With many years of experience and proven manufacturer know-how, ensures the reliable operation and long service life of your system.

Inspecting service all the life, guiding and safeguard maintaining.

Keep in touch with ordering unit regularly, pay a return visit regularly , so as to ensure user's equipment normal running.

When pumps are repaired, we will be recorded in the history file.

The equipment upgrades and improvement

Free offering the scheme of improving for user's charge;

Offering economical and practical improvement products and fittings.

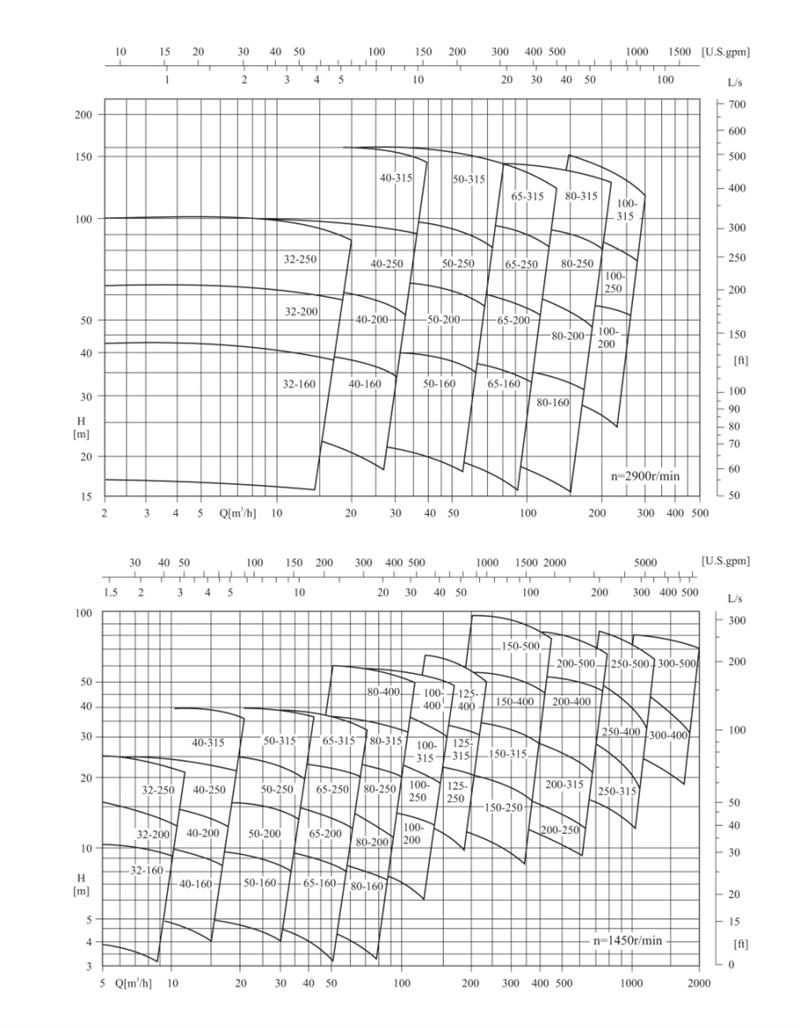

TECHNICAL DATA

Diameter: 32~300 mm

Capacity: ~2000 m /h

Head: ~160 m

Working pressure: ~2 .5 MPa

Working temperature: -80 ~+150℃

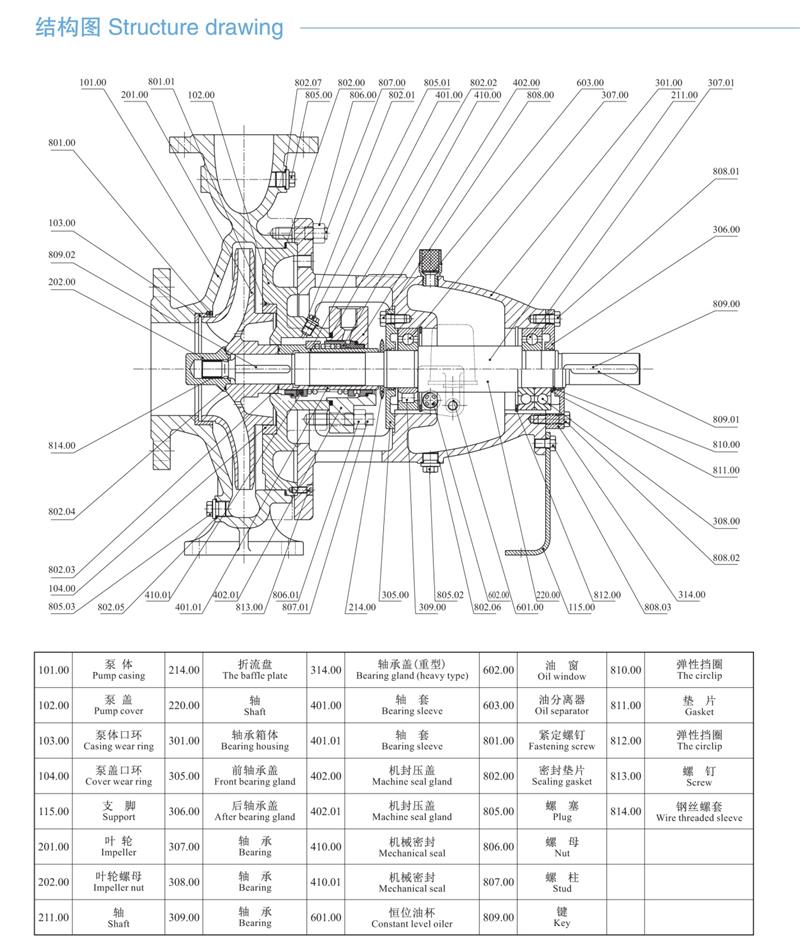

Characteristics of structure

CASING : Foot support structure

IMPELLER: Close impeller. Thrust force of CZ series pumps are balanced by back vanes or balance holes, rest by bearings.

COVER : Along with seal gland to make sealing housing, standard housing should be equipped with various kinds of seal types.

SHAFT SEAL :According to different purpose, seal can be mechanical seal and packing seal. Flush can be inner-flush, self-flush, flush from outside etc, to ensure good work condition and improve life time.

SHAFT: With shaft sleeve, prevent shaft from corrosion by liquid, to improve life time. Back pull-out design Back pull-out design and extended coupler, without taking apart discharge pipes even motor, the whole rotor can be pulled out, including impeller, bearings and shaft seals, easy maintenance.

APPLICANT

Pump Applicant

Sea water plant

Seawater desalination project

Refinery or steel plant

Power plant

Making of paper, pulp, pharmacy, food, sugar etc.

Refinery

Petrochemical industry

Coal processing industry and low temperature project

For transferring:

corrosive Sea water.

Inorganic acid and organic acid in different temperature and content, like sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid etc.

Alkaline solutions like sodium hydroxide solutions and sodium carbonate solutions etc in different temperature and content.

Various kinds of salt solution.

Different liquid petro-chemical products, organic compounds, and other corrosive materials and products.

At present, corrosion-proof materials can meet all above requirements. Once acquirement, users should give detailed information of transferred liquid.

Part of Sample Project

seth@tkflow.com

seth@tkflow.com