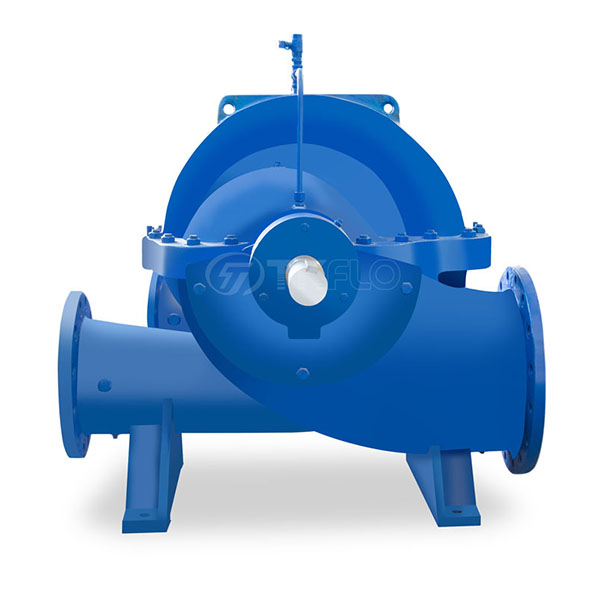

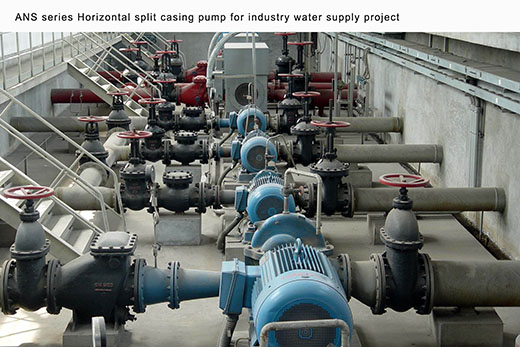

Model ASN and ASNV pumps are single stage double suction split volute casing(case) centrifugal pump is the new generation of high performance single stage double suction centrifugal pump, mainly used for water plant, air conditioning, water recycling, heating systems, and high-rise building water supply, irrigation and drainage pumping stations, power plants, industrial water supply system, Fire systems, shipbuilding industry, and other places of fluid transmission.

Model Meaning

| ANS(V) 150-350(I)A | |

| ANS | Split casing horizontal centrifugal pump |

| (V) | Vertical type |

| 150 | Outlet diameter of pump 150mm |

| 350 | Nominal diameter of impeller 350mm |

| A | Impeller via first cutting |

| (I) | As flow-expanded type |

ASN Horizontal type pump

ASNV Vertical type pump

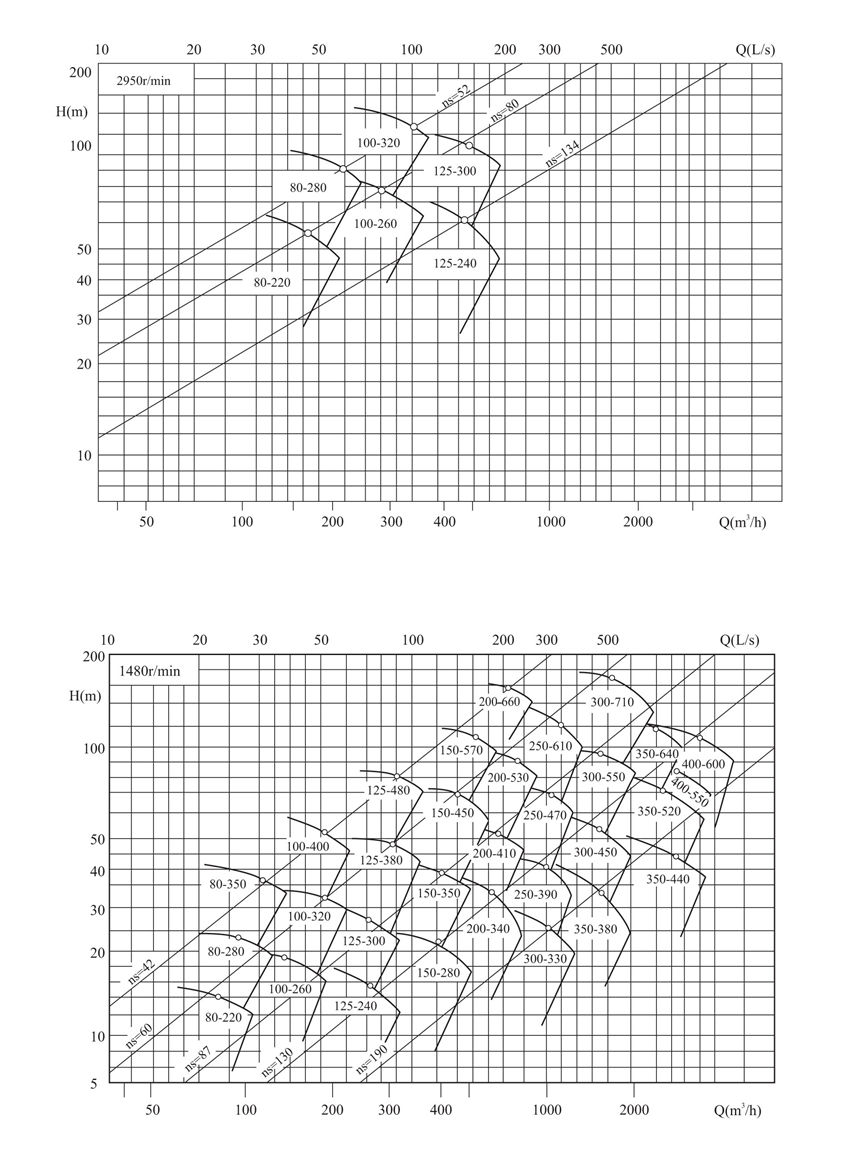

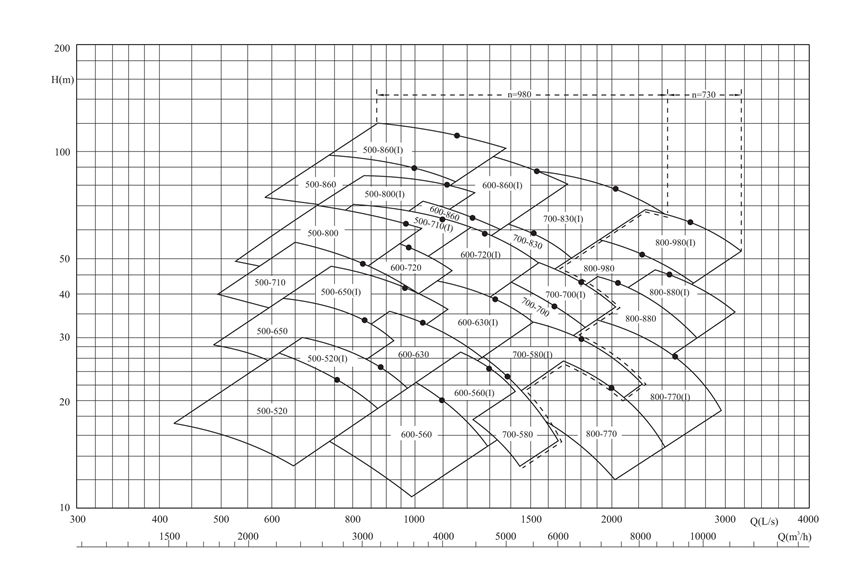

TECHNICAL DATA

Operation Parameter

| Diameter | DN 80-800MM |

| Capacity | No more than 11600m³/h |

| Head | No more than 200m |

| Liquid Temperature | Up to 105℃ |

Advantage

1.Compact structure nice appearance, good stability and easy installation.

2.Stable running the optimally designed double-suction impeller makes the axial force reduced to the minimum and has a blade-style of very excellent hydraulic performance, both internal surface of the pump casing and the impeller s surface, being precisely cast, are extremely smooth and have a notable performance vapor corrosion resisting and a high efficiency.

3. The pump case is double volute structured, which greatly reduces radial force, lightens bearing's load and long bearing's service life.

4.Bearing use SKF and NSK bearings to guarantee a stable running, low noise and long duration.

5.Shaft seal use BURGMANN mechanical or stuffing seal to ensure a 8000h non-leak running.

6 . Flange standard: GB, HG, DIN, ANSI standard, according to your requirements.

Recommended Material Configuration

| Recommended Material Configuration (For reference only) | |||||

| Item | Clean water | Drink water | Sewage water | Hot water | Sea water |

| Case & Cover | Cast iron HT250 | SS304 | Ductile iron QT500 | Carbon steel | Duplex SS 2205/Bronze/SS316L |

| Impeller | Cast iron HT250 | SS304 | Ductile iron QT500 | 2Cr13 | Duplex SS 2205/Bronze/SS316L |

| Wearing ring | Cast iron HT250 | SS304 | Ductile iron QT500 | 2Cr13 | Duplex SS 2205/Bronze/SS316L |

| Shaft | SS420 | SS420 | 40Cr | 40Cr | Duplex SS 2205 |

| Shaft sleeve | Carbon steel/SS | SS304 | SS304 | SS304 | Duplex SS 2205/Bronze/SS316L |

| Remarks: Detailed material list will according to liquid and site conditions | |||||

NOTE before order

Parameters necessary to be submitted at order Industry Circulating water pump with Electrical motor.

1. Pump model and the flow, head (including the system loss), NPSHr at the point of the desired working condition.

2. Type of shaft seal (must be noted either mechanical or packing seal and, if not, delivery of the mechanical seal structure will be made).

3. Moving direction of the pump (must be noted in case of a CCW installation and, if not, delivery of a clockwise installation will be made).

4. Parameters of the motor (Y series motor of IP44 is generally used as the low-voltage motor with a power <200KW and, when to use a high voltage one, please note its voltage, protective rating, insulation class, way of cooling, power, number of polarity and manufacturer).

5. The materials of pump casing, impeller, shaft etc. parts. (delivery with the standard allocation will be made if without being noted).

6. Medium temperature (delivery upon a constant-temperature medium will be made if without being noted).

7. When the medium to be transported is corrosive or contains solid grains, please note the features of it.

seth@tkflow.com

seth@tkflow.com